INTRODUCTION

There existed for many years an air of mystery surrounding the selection, heat treatment and use of tool steels. Started by the secretiveness of the early makers, it has been fostered somewhat by the seemingly never-ending introduction of new grades.

Fig 1: Halcomb Steel Company, Syracuse, New York - Dreadnought tool steel advertisement - 1913. |

Today the term tool steel commonly means hard steel of a quality used for making tools for cutting and other purposes. More specifically it refers to varieties of carbon and alloy steels that are particularly well-suited to be made into tools.

For the purposes of this historical survey the author has divided the tool steels into five basic types or groups: water-hardening carbon tool steels, oil hardening tool steels, shock-resisting tool steels, air hardening tool steels; and high-speed steels.

The survey also covers the non-ferrous cutting tool alloys. Although technically not steels, they are a group of tool alloys which crop up more often than may be expected. Furthermore, they are quite useful for certain purposes and operations in the metal shop.

A BRIEF OUTLINE OF HSS CLASSIFICATION

During the 1970s the American Society for Testing and Materials (the ASTM is now ASTM International) introduced a unified numbering system for steel comprising 11 main classes each designated by a letter as follows:

| W: | Water-Hardening | |

| S: | Shock-Resisting | |

| O: | Cold-Work (Oil-Hardening) | |

| A: | Cold-Work (Medium-Alloy, Air-Hardening) | |

| D: | Cold-Work (High-Carbon, High-Chromium) | |

| L: | Low-Alloy | |

| F: | Carbon-Tungsten | |

| P: | P1-P19: | Low-Carbon Mould Steels |

| P20-P39: | Other Mould Steels | |

| H: | H1-H19: | Chromium-Base Hot Work |

| H20-H29: | Tungsten-Base Hot Work | |

| H40-H59: | Molybdenum-Base Hot Work | |

| T: | High-Speed (Tungsten-Base) | |

| M: | High-Speed (Molybdenum-Base) | |

The current ASTM standard recognises 7 tungsten types and 21 molybdenum types of HSS. In this unified numbering system the tungsten-type HSS grades (e.g. T1, T15) are assigned numbers in the T120xx series, while molybdenum (e.g. M2, M48) and intermediate types are T113xx.

The current standard (ASTM A600) covers types T1, T2, T4, T5, T6, T8, and T15 and molybdenum-type high-speed steels M1, M2, M3, M4, M6, M7, M10, M30, M33, M34, M36, M41, M42, M43, M44, M46, M47, M48, and M62 in the form of annealed, hot-rolled bars, forgings, plate, sheet, or strip, and annealed, cold-finished bars or forgings used primarily in the fabrication of tools. Two intermediate high speed tool steels designated as M50 and M52 are also covered.

Water-Hardening Tool steels include all class W tool steels. These steels do not retain hardness well at elevated temperatures, but they do have high resistance to surface wear. Typical applications include blanking dies, files, drills, taps, countersinks, reamers, jewellery dies, and cold-striking dies.

THE HIGH SPEED STEELS (HSS)

Just what is high speed steel or HSS? Well when tool steels contain a combination of more than 7.0% tungsten, molybdenum and vanadium, along with more than 0.6% carbon, they are referred to as high speed steel. HSS is a highly-alloyed tool steel capable of maintaining hardness at elevated temperatures better than the high carbon and low alloy steels. This good hot hardness permits tools made of HSS to be used at higher cutting speeds (hence the name “High-Speed”). Since the early 1900s a wide variety of high speed steels has been and continues to be available. For the most part these steels can be divided into two basic types: Tungsten-type, designated T-grades by the AISI; and Molybdenum-type, designated M-grades by the AISI.

Fig 2: Armstrong Whitworth & Co., Manchester, U.K. - Three Celebrated Brands of HSS - 1911. |

The term HSS includes all the molybdenum (M1 to M52) and tungsten (T1 to T15) class alloys.

These steels require high temperatures for hardening. The molybdenum types are usually hardened from a range of 1200°C (2200°F) to 1235°C (2250°F), the tungsten types as a rule from 1260°C (2300°F) to 1290°C (2350°F) when heat treated in an atmosphere controlled furnace. High-speed tools steels may be hardened to 62-67 HRc and maintain that hardness in service temperatures as high as 540°C (1000°F) making them very useful in high-speed machining.

Tungsten-type HSS: The tungsten steels form the oldest class and are an outgrowth of the even older Mushet steels. Their development started in the 19th century with Robert Mushet in UK and reached a technical flowering with the work of F W Taylor and M White in the USA just as the 20th century dawned.

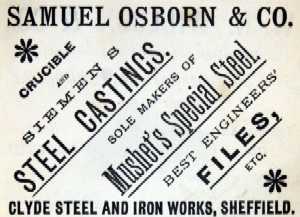

Robert F Mushet practiced the addition of manganese to the steel. But he didn’t stop there; he continued experimenting and sometime in 1868 eventually discovered self-hardening steel. This new steel was immediately put into the market under the name “R Mushet’s Special Steel” or "R.M.S". A typical analysis of this steel was 2.4% carbon, 5.9% tungsten, and 2.5% manganese (these were the proportions of the original R.M.S made at Coleford - the R.M.S made at Sheffield contained 0.55% chromium). Unfortunately for Mushet, the company organised to manufacture and sell his new steel did not succeed well in business. Some three years later the production of Mushet steel was taken over by Samuel Osborn & Co Ltd at the Clyde Works, Sheffield.

Fig 3: Samual Osbourne & Co., Sheffield, U.K. - Mushnet HSS advertisement - 1903. |

With a better business model the wide introduction of the new steel into engineering works and its imitation under the name of air-hardening or self-hardening steel quickly followed. Clearly a substantial advance had been made in the art of cutting metals. It was now possible to turn or plane at double or triple the former speeds; and to machine pieces which were formerly just too hard for the tools available or so hard as to make the cost of operation prohibitive. But even after gaining general use in engineering works, Mushet tools were little used for increasing speeds – most usually they were only used to save frequent grindings or to permit doing jobs previously impossible.

It took a further 25 years after ‘Mushet’ or ‘self-hardening’ steel had become an established fact in engineering before the marvellous properties latent in it were clearly appreciated and the industrial world caught a glimpse of what promised to be a revolution in machine shop methods.

Frederick W Taylor had begun experimenting with Mushet and other self-hardening steels as far back as 1894. His aim was to determine which steels were best suited to special kinds of work. So shortly after taking charge of the Bethlehem steel works in 1898 he formed an association with Maunsel White and others in order to better undertake the work at hand.

Fig 4: Samual Osbourne & Co., Sheffield, U.K. - Mushnet HSS advertisement - 1912. |

Before the introduction of HSS in the USA the term ‘Mushet steel’ meant self-hardening tool steels containing tungsten. These early ‘Mushet’ steels contained from 5-8% tungsten, up to 2.5% manganese, and very high carbon (1.5-2.4%) with sometimes 0.5% chromium. The Mushet steel made by Samuel Osborn & Co Ltd in 1868 and branded ‘Self-Hard’ or R.M.S. had a typical analysis of 8% tungsten, 2% carbon, and 1% manganese.

The Taylor and White experiments from 1893 to 1898 led to a new steel with less carbon. Taylor-White steel of c.1900 contained 1.85% carbon, 8% tungsten, 3.8% chromium, and 0.3% manganese. Finally, on 19 February 1901, Taylor and White received a patent for a ‘Metal-Cutting Tool and Method of Making Same’ such a tool being "specially adapted for cutting very hard metal and capable of running efficiently when cutting such metals at higher speeds and greater temperatures than has heretofore been practicable".

The investigations by Taylor and White, which culminated in the development of ‘high speed steel’, required a very large amount of money to be spent and infinite patience to be exercised. Something like 50,000 recorded tests were made, a great many more were not recorded, and close to one million pounds of steel and iron was cut into chips; the estimated total cost was almost $200,000.

Fig 5: Arthur Balfour and Co, Sheffield, U.K. - Super Capital high speed steel toolbits - 1963. |

However, this was by no means the end of experiments with HSS. In 1904 the addition of vanadium was patented by the Crucible Steel Company and this led to the formulation of what is perhaps the best-known grade, the 18-4-1 steel (later known simply as T1). Cobalt in HSS was first reported in 1912 by Becker in Germany. In 1939 high-carbon high-vanadium super high-speed tool steels (M4 and Tl5) were introduced. The M40 series high-carbon high-cobalt super hard high-speed tool steels first appeared in 1961.

Material availability and costs also had an effect on the development of HSS. Due to the shortage of tungsten and the increases in its price, molybdenum bearing high speed steels were introduced in the USA around 1930.

Since first being patented by the Crucible Steel Company the composition of the T1 type with 18% W has not changed. Indeed, it remained the main type of HSS used in engineering workshops up until the 1940s. Today however only 5-10% of the HSS in Europe is of the T1 type and only about 2% in the USA.

Tungsten HSS can be divided into two general grades according to tungsten content being those with 18% and 14% tungsten. The Super HSS or Cobalt HSS are high in tungsten, but also contain considerable quantities of cobalt. They have added red hardness, but are inclined to be brittle.

Molybdenum-type HSS: Molybdenum rich HSS such as M1 has been in general use since the 1930s. It eventually gained market leadership in the USA during the 1940s. Molybdenum HSS is an outgrowth of an early attempt by the US Ordinance Department to substitute molybdenum for the costly and imported tungsten in HSS. The first Watertown Arsenal steel of 1940 contained about 0.8% carbon, 9.5% molybdenum, 4% chromium, 1.5% tungsten, and 1% vanadium. But the earliest known molybdenum “self-hardening” steel was the ‘MoSH’ steel made by the Sanderson Steel Company in 1898.

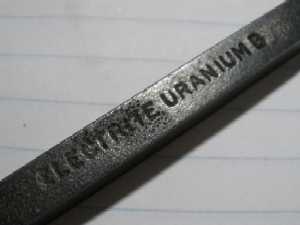

Fig 6: Latrobe Electric Steel Co., Pennsylvania, U.S. - Electrite Uranium HSS advert in American Machinist Vol 53 Number 1 - 1920. |

Many types of molybdenum HSS came onto the market in the USA. For example, Motung high speed steel (M1) was patented by the Cleveland Twist Drill Company and contains 0.75% C, 8% Mo, 1.75% W, 4% Cr, and 1.25% V. The name Mo-Tung is also used by the Universal-Cyclops Steel Corporation for this steel and other trade names for it include Mogul, Tatmo, Mo-Cut, Vul-Mo, Mohican, LMW, Rex T-Mo, HM Steel, and Di-Mol. Van Lom HSS by the Vanadium-Alloys Steel Company has 1% C, 9% Mo, 4.25% Cr, and 4% V. Bethlehem 66 HSS (M2) by the Bethlehem Steel Company contains 0.8% C, 5.5% W, 5% Mo, 4% Cr and 1.75% V. More often than not the product outlasted the company that made it.

The addition of about 10% of tungsten and molybdenum in total most efficiently maximises the hardness and toughness of high speed steel and maintains these properties at the high temperatures generated when cutting metals. Molybdenum has twice the effect of tungsten in terms of red hardness, but it makes the steel more brittle and also subject to decarburisation. Standard tungsten high speed steels are therefore sometimes modified with very small amounts of molybdenum.

The old Damascus steel and Toledo steel were molybdenum steels, the molybdenum being in the original ore. Damascene steel refers to the wavy forging marks on blades and was not necessarily a molybdenum steel. But the original Wootz steel, or Indian steel, of this type contained small percentages of aluminium incorporated in some obscure manner. Wootz steel was made in the crucible, although the crucible method was not used in Europe until 1740.

Fig 7: Vascoloy-Ramet Corp(VR) - Tantung tool catalog - circa 1940. |

So, what is high speed steel used for? The main use of HSS continues to be in the manufacture of various cutting tools: lathe tools, drills, taps, milling cutters, gear cutters, saw blades, etc, although usage for punches and dies is increasing. Tool steel, in particular HSS, can also be surface treated by nitriding, laser or plasma overlays of hard coatings (e.g. Stellite) as well as by chemical or physical vapour deposition of hard carbides and nitrides. This new coating technology has extended the use of HSS.

While coatings, such as TiN, TiAlN or CrAlN significantly increase tool life, they also increase tool cost. Nevertheless, most tools in the higher-end applications today are coated as the higher cost is well balanced by the greater productivity during the machining processes.

No one composition of high-speed tool steel can meet all cutting tool requirements. The general-purpose molybdenum steels such as M1, M2, and M7 and tungsten steel T1 are more commonly used than other high-speed tool steels. They have the highest toughness and good cutting ability, but they possess the lowest hot hardness and wear resistance of all the high-speed tool steels. The addition of vanadium offers the advantage of greater wear resistance and hot hardness, and steels with intermediate vanadium contents are suited for fine and roughing cuts on both hard and soft materials.

The 5% vanadium steel (T15) is especially suited for cutting hard metals and alloys or high-strength steels, and is particularly suitable for the machining of aluminium, stainless steels, austenitic alloys, and refractory metals. Wrought high-vanadium high-speed tool steels are more difficult to grind than their particle metallurgy product counterparts.

The addition of cobalt in various amounts allows still higher hot hardness, the degree of hot hardness being proportional to the cobalt content. Although cobalt steels are more brittle than the non-cobalt types, they give better performance on hard, scaly materials that are machined with deep cuts at high speeds.

High-speed tool steels have continued to be of importance in industrial commerce for 70 to 80 years despite the inroads made by competitive cutting tool materials such as cast cobalt alloys, cemented carbides, ceramics, and cermets. The superior toughness of high speed tool steel seems to guarantee it a continuing niche in the cutting tool materials marketplace.

HSS COMPOSITION: THE EFFECT OF SOME KEY CHEMICAL ELEMENTS

The essential elements of a steel either alone or combined with the addition of other elements is what gives the steel its inherent cutting performance, red-hardness, toughness, wear-resistance, etc. It is difficult to enumerate all the wonderful qualities steel acquires when various elements are introduced in it.

Fig 8: Electrite Uranium B tool bit. |

Nevertheless, here is a summary of most of the principal alloying elements and their effect on HSS.

NOTE: All percentages given are by weight

Aluminium (Al) – Aluminium is the most effective and frequently used deoxidiser in steelmaking. Small additions are used to insure small grain size. It will combine with nitrogen and form hard aluminium nitrides, which is why it is added to nitriding steels.

Boron (B) - Boron is added to unalloyed and low alloyed steels to enhance the hardness level through enhancement hardenability. Boron added to HSS, for example, containing 18%W, 4%Cr and 1%V, enhances the cutting performance, but reduces the forging qualities.

Carbon (C) - As in all tool steels, carbon is essential to the hardenability of steel. It increases tensile strength and edge retention and improves resistance to wear and abrasion. Added in isolation, it decreases toughness. Also, it is evident that, as the wearing properties and high hot hardness depend on the presence of massive amounts of complex alloy carbides, carbon is of prime importance. The usual carbon range for high speed steels is 0.65-1.5%, of which about 0.3% is dissolved in the matrix. The hardness on the finished product increases rapidly up to about 1.0% carbon. The higher carbon grades show a fairly marked fall off in ductility.

Chromium (Cr) - Added for increased wear resistance, hardness, tensile strength, and for corrosion resistance. Cr forms large, complex carbides. A steel with at least 13% chromium is typically deemed "stainless", though another definition says the steel must have at least 11.5% free chromium (as opposed to being tied up in carbides) to be considered "stainless". Adding Chromium in high amounts decreases toughness. Chromium is a carbide-former, which is why it increases wear resistance. Unfortunately, the amount of free Chromium in the steels is almost never specified. Addition of 4% chromium is made to all high speed steels with the prime purpose of promoting depth hardening. Chromium in the absence of large quantities of retained austenite sharply retards the rate of softening in these steels, but in itself does not produce a true secondary hardening peak.

Fig 9: James Neill & Co., Sheffield, U.K. - Box of Eclipse Cobalt HSS Tool Bits. |

Cobalt (Co) - Increases red hardness, also allows for higher quenching temperatures (during the heat treatment procedure). Intensifies the individual effects of other elements in more complex steels. Co is not a carbide former, however adding Cobalt to the alloy allows for higher attainable hardness and higher red hot hardness. Cobalt is optional as an alloy addition, being present in only a few of the "super grades" up to about 10% maximum, although a few special steels have higher additions. The addition of cobalt can raise the hardness by as much as 60HV, depending on the specific grade of steel. Its prime purpose is to promote red hardness, however this comes at the expense of impact strength.

Lead (Pb) - Although virtually insoluble in liquid or solid steel, lead is sometimes added to carbon steels via mechanical dispersion during pouring in order to improve machinability.

Manganese (Mn) - An important element, Manganese improves grain structure and contributes to hardenability, strength, and wear resistance. Improves the steel, deoxidizes and degasifies during steel manufacture (hot working and rolling). In larger quantities, increases hardness and brittleness.

Molybdenum (Mo) - A carbide former, prevents brittleness, and maintains strength at high temperatures. Improves machinability and resistance to corrosion. Present in many High Speed steels, and air-hardening steels (e.g. A2, ATS-34) always have 1% or more Molybdenum.

Nickel (Ni) - Adds toughness. Nickel is widely believed to play a role in corrosion resistance as well, but this is probably incorrect.

Niobium (Nb) formerly Columbium (Cb) - heat treatment of the niobium-bearing steel yields fine edged carbides, which makes the steel very tough. The introduction of niobium prevents embrittlement and improves wear resistance. In small amounts, niobium can significantly increase the yield strength and, to a lesser degree, tensile strength of steels.

Tungsten (W) - formerly known as Wolfram. Strongest carbide former after Nb and then V. W increases wear resistance. When combined properly with Chromium or Molybdenum, Tungsten will turn a steel into a High-Speed steel. The M2 high-speed steel has a high amount of tungsten; around 6%.

Vanadium (V) - Contributes to wear resistance and hardenability, and as a carbide former (in fact, vanadium carbides are the hardest carbides) it contributes to wear resistance. It also refines the grain of the steel, which contributes to toughness and allows the steel to take a very sharp edge. A number of steels contain some Vanadium, whereas M2, Vascowear, and CPM 10V, S90V, S125V (in order of increasing amounts) feature very high amounts of Vanadium. This element is always present to a minimum of 1% and generally up to 2% or 3%. It can be higher in very highly alloyed grades. Vanadium forms extremely stable carbides such as VC or V4C3, which are virtually insoluble at normal hardening temperatures, and thus create a very effective means of limiting grain growth.

Zirconium (Zr) - the presence of zirconium compounds reduces grain coarsening, and thus permits the use of higher hardening or carburising temperatures. It produces only slight changes in the mechanical properties of quenched and tempered steels which are generally beneficial. It produces a more uniform distortion during heat treatment than other alloying elements like vanadium. In high alloys steels, it increases hardness but decreases ductility.

TYPES, BRANDS AND MAKERS

HSS is sold under a myriad of trade names in rods, bars, flats and tool shapes. For this reason it is an all-too-often occurrence to come across a piece of branded HSS and have no idea what type or grade of HSS it is or perhaps even be unsure if it is or is not HSS.

The following information was compiled in an attempt to untangle the composition and principal uses of the many brand name tool steels (HSS and carbon) as well as introduce some of the very useful non-ferrous cutting tool alloys.

But what about Chinese and Indian tools steels? Well it is a bit of a mixed bag really. Some of these ‘imports’ perform quite well, but how can a purchaser know what these are and so avoid some of the lesser quality bits?

First it may be of help to know that of the many grades of HSS made in China, two are simply referred to as “economical” HSS. These are by analysis:

W 4% Cr 4% Mo 3% V nil%

W 3% Cr 4% Mo 2% V 2%

Clearly alongside the other HSS grades listed in the tables below these “economical” HSS grades contain comparatively low levels of tungsten and molybdenum. Not sure what the carbon content is. These are probably the types of HSS used in those very ‘economical’ boxes of drill bits and in similar versions of taps and dies labelled “HSS China”.

Just the poor finish and lack of care in grinding and sharpening these tools should be enough to put you on guard. If not you may soon find out that “economical” Chinese HSS may have some performance issues. Of course you can also buy good quality Chinese HSS.

TYPE “T” Tungsten-Rich HSS

T1 (18-4-1) typical analysis (%): C 0.7; W 18; Cr 4.0; V 1.0 – this is the original 18-4-1 high speed steel introduced around 1904. Still held up as a standard general purpose tool steel. It has a balanced combination of shock resistance and abrasion resistance. It is the easiest HSS to machine. Has high red hardness.

Principal application is for cutting tools.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T1 | A.2 | Comsteel, Waratah NSW Australia | |

| T1 | Achorn Kloster Brilliant AX | Achorn Steel Co, Boston MA USA |

|

| T1 | B6 | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| T1 | Blue Chip | Firth Sterling Inc, Pittsburgh PA USA | W 18; Mn 0.25 |

| T1 | Bohler S200 | Bohler Edelstahl GmbH | |

| T1 | Buckeye T1 | Time Steel Service Inc, USA | |

| T1 | Clarite | Columbia Tool Steel Co, Columbia IL USA | |

| T1 | Clipper | (?) | Maker unknown |

| T1 | DoAll T1 | DoAll Co, Des Plaines IL USA | |

| T1 | Double Mushet ND | Samuel Osborn & Co, Sheffield England | |

| T1 | Dreadnaught | Hawkridge Brothers Co, Boston MA USA | W 18 |

| T1 | Dreadnought | Crucible Steel Co of America, Pittsburgh PA USA | W 18; Mn 0.28 |

| T1 | E T1 | Erasteel Inc (France and Sweden) | |

| T1 | Electrite No.1 | Latrobe Steel Co, Latrobe PA USA | |

| T1 | Electrite No.1 XL | Latrobe Steel Co, Latrobe PA USA | |

| T1 | Fagersta D-921 | Fagersta Stainless AB, Sweden | |

| T1 | Fagersta FB-T1 | Fagersta Bruks, Sweden | |

| T1 | FMP 622 | F M Parkin Ltd, Sheffield England | |

| T1 | Heva-Super Bono | Sidenor SA, Greece | |

| T1 | Kasle KT-1 | Kasle Steel Co | |

| T1 | KE881 | Sanderson Kayser Ltd | |

| T1 | KutKwik | Henry Disston & Sons Inc, Philadelphia PA USA | |

| T1 | LXX | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | |

| T1 | Motor Maximum | Richard W Carr Ltd, Pluto Works, Sheffield England | |

| T1 | No.1 | Houghton & Richards Inc, Boston MA USA | |

| T1 | Red Cut Superior | Teledyne Vasco, Latrobe PA USA | |

| T1 | Red Streak | Simonds Saw & Steel Co, Lockport NY USA | |

| T1 | Rex AA | Crucible Specialty Metals Co, NY USA | |

| T1 | SaBeN Extra | Sanderson Bros & Newbould, Sheffield / Sanderson Kayser Ltd | |

| T1 | Spartan No.7 | Atlas Steels Ltd, Welland, Ontario, Canada | General purpose |

| T1 | Spartan-5 | Atlas Steels Ltd, Welland, Ontario, Canada | C 0.5 |

| T1 | Special HS | Bethlehem Steel Co, Bethlehem PA USA | 18-4-1 HSS |

| T1 | Special M | Stones Steels | |

| T1 | Stag Special | Balfour Darwins Ltd, Sheffield, England | |

| T1 | Star Zenith | Carpenter Steel Co, Reading PA USA | |

| T1 | Super 18 | F M Parkin (Sheffield) Ltd, England | |

| T1 | Super HS | Ziv Steel & Wire Co, USA | |

| T1 | Super Rapid | Cooks Steels | |

| T1 | Supremus Extra | Jessop Steel Co, Washington PA USA | |

| T1 | Supremus T-1 | Jessop Steel Co, Washington PA USA | |

| T1 | T-1 | Bethlehem Steel Co, Bethlehem PA USA | |

| T1 | T-1 | Republic Steel Corp, Cleveland OH USA | |

| T1 | Ultra Capital | Arthur Balfour & Co Ltd / Eagle & Globe Steel Co Ltd, Sheffield | the standard quality for lathe tools – introduced in 1908 |

| T1 | Usaspead Super | Macready’s Metal Co Ltd, London, England | |

| T1 | V | McInnes Steel Co, Corry PA USA | |

| T1 | Vinco | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T1 | Witten Wolfram 184 | Thyssen Specialty Steels Inc | |

| T1 | Ziv Super | Ziv Steel & Wire Co USA |

T2 typical analysis (%): C 0.8; W 18.0; Cr 4.0; V 2.0; Mo 0.8 – with higher carbon and vanadium content than T1 and a small molybdenum addition this steel provides a harder and more durable tool edge. Often more economical than cobalt steels it hardens without a soft skin. Not as tough as T1.

Suitable for fine edge tools such as hobs and threading dies, form tools, twist drills, reamers, broaches and milling cutters.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T2 | Achorn T2 High Speed | Achorn Steel Co, Boston MA USA | |

| T2 | B9 | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| T2 | Bohler S201 | Bohler Edelstahl GmbH | |

| T2 | Buckeye T2 | Time Steel Service Inc | |

| T2 | E.V.M or EVM | Teledyne Vasco, Latrobe PA USA | |

| T2 | Electrite No.19 | Latrobe Steel Co, Latrobe PA USA | |

| T2 | Electrite No.19 XL | Latrobe Steel Co, Latrobe PA USA | |

| T2 | FMP 842 | F M Parkin Ltd, Sheffield England | |

| T2 | HV Blue Chip | Firth Sterling Inc, Pittsburgh PA USA | |

| T2 | Lockport Special | Simonds Saw & Steel Co, Lockport NY USA | |

| T2 | ML | Ludlum Steel Co / Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | Originally W 18; Cr 4; V 1.85; Mo 0.5 |

| T2 | No.2 | Houghton & Richards Inc, Boston MA USA | |

| T2 | Novo 2 | H Boker & Co, | |

| T2 | Rex Supervan or Super Van | Crucible Specialty Metals Co, NY USA | |

| T2 | Super Star Zenith | Carpenter Steel Co, Reading PA USA | |

| T2 | Supremus Extra | Jessop Steel Co, Washington PA USA | |

| T2 | Trojan | Atlas Steels Ltd, Welland, Ontario, Canada | General purpose |

| T2 | Tunco | Simonds Saw & Steel Co, Lockport NY USA | |

| T2 | Twin Van | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T2 | Vanite | Columbia Tool Steel Co, Columbia IL USA |

T3 typical analysis (%): C 1.0; W 18.0; Cr 4.0; V 3.0; Mo 0.7 – the triple vanadium and high carbon content of this steel provide the highest wear resistance of any tool steel. It is suitable for cutting hard wrought metals or castings, material that work hardens and soft gummy materials where wear resistance is a major factor.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T3 | Electrite Vanadium | Latrobe Steel Co, Latrobe PA USA | |

| T3 | Electrite Van-XL or Vanadium XL | Latrobe Steel Co, Latrobe PA USA | |

| T3 | No.3 | Houghton & Richards Inc, Boston MA USA | |

| T3 | Rex 939 | Crucible Specialty Metals Co, USA |

T4 typical analysis (%): C 0.75; W 18.0; Cr 4.0; V 1.0; Co 5.0; Mo 0.8 – the addition of 5% cobalt to T1 increases cutting ability at high temperatures, making this steel suitable for hogging cuts where high heats develop. Should be used where tools are well supported, not subject to shock and ground all over after hardening.

Generally used for cutting tools, broaches and cold extrusion punches.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T4 | 455 Cobalt | F M Parkin (Sheffield) Ltd, England | |

| T4 | Acmite | Columbia Tool Steel Co, Columbia IL USA | |

| T4 | B.2 | Comsteel, Australia | |

| T4 | B7 | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| T4 | Blue Chip | Firth Sterling Inc, Pittsburgh PA USA | Standard 18-4-1 HSS an old standby since c.1900 |

| T4 | Cobalt | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T4 | Cobalt | Houghton & Richards Inc, Boston MA USA | |

| T4 | CoMoKut | Bethlehem Steel Co, Bethlehem PA USA | 18-4-1 HSS with Co 5.0 |

| T4 | D-6-Co | Henry Disston & Sons Inc, Philadelphia PA USA | C 0.8; W 19.0; Cr 4.0; V 2.0; Co 6.0 |

| T4 | Eclipse H5 | James Neill Tools, Sheffield England | Made to BT4 (AISI: T4) C 0.8; W 18.5; Cr 4.5; V 1.25; Co 5.0 |

| T4 | Electrite Cobalt | Latrobe Steel Co, Latrobe PA USA | |

| T4 | FS 1-5 | Firth Sterling Inc, Pittsburgh PA USA | |

| T4 | Kerau Wunda | Sanderson Kayser Ltd, | |

| T4 | Panther Special | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | Less Co than Super Panther |

| T4 | Powhattan | Atlas Steels Ltd, Welland, Ontario, Canada | For high cutting edge temperature |

| T4 | Purple Label | Jessop Steel Co, Washington PA USA | |

| T4 | Red Chip | Firth Sterling Inc, Pittsburgh PA USA | Formerly FS 1-5 |

| T4 | Red Cut Cobalt | Vanadium-Alloys Steel Co / Teledyne Vasco, Latrobe PA USA | |

| T4 | Rex AAA | Crucible Specialty Metals Co, NY USA | Outstanding tool bit for general purpose applications |

| T4 | Triple Mushet MD | Samuel Osborn & Co, Sheffield England | |

| T4 | Tunco | Simonds Saw & Steel Co, Lockport NY USA | |

| T4 | Ultra Capital Plus One (or +1) | Arthur Balfour & Co Ltd, Sheffield, England / Darwins Alloy Castings / Steelmark Eagle & Globe | C 0.85; Cr 4.25; W 18.0; V 1.5 and Co 5.0 - long life in general work and heavy cutting |

| T4 | Usaspead Supreme | Macready’s Metal Co Ltd, London, England | W 20; Co 5 |

T5 typical analysis (%): C 0.8; W 18.5; Cr 4.0; V 1.75; Co 8.0; Mo 0.8 – the ultimate in HSS for heavy duty cutting. Has a combination of red hardness and toughness that results in outstanding performance. Recommended for heavy duty lathe, planer and boring tools. Especially adapted for cutting hard, gritty material such as cast iron or steel, also heat treated alloy steels. Best used in tools that are well-supported and not subject to excessive shock or chattering. Cutting speeds can be about 25% faster than T1 with higher tool life.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T5 | B10 | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| T5 | Bonded Carbide Jr | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T5 | Circle C | Firth Sterling Inc, Pittsburgh PA USA / Teledyne Vasco, Latrobe PA USA | C 0.75; W 18.5; Cr 4.5; V 2.0; Mo 1.0; Co 9.0 - durable, heavy duty super HSS with unusual red hardness – recommended for alloy steel, high magnesium steel, cast iron, cast steel, heat treated steel and stainless steel |

| T5 | Cobalt 10 | Ossenberg | |

| T5 | Cobite | Columbia Tool Steel Co, Columbia IL USA | |

| T5 | Darwin 505 Special | Darwin & Milner Inc, Cleveland OH USA | |

| T5 | DoAll T-5 | DoAll Co, Des Plaines IL USA | |

| T5 | Electrite Super Cobalt | Latrobe Steel Co, Latrobe PA USA | |

| T5 | Electrite Super Cobalt XL | Latrobe Steel Co, Latrobe PA USA | |

| T5 | Extra Triple Mushet | Samuel Osborn & Co, Sheffield, England | |

| T5 | Milco 9 | A Milne & Co, New York NY USA | |

| T5 | Nipigon | Atlas Steels Ltd, Welland, Ontario, Canada | For high cutting edge temperature |

| T5 | No.4 | Houghton & Richards Inc, Boston MA USA | |

| T5 | Purple Label Extra | Jessop Steel Co, Washington PA USA | |

| T5 | Red Cut Cobalt B | Vanadium Alloys USA | |

| T5 | Rex Super Cut (or Supercut) | Crucible Specialty Metals Co, NY USA | |

| T5 | SaBeN Tenco | Sanderson Kayser Ltd, | |

| T5 | Super Cobalt | Latrobe Steel Co, Latrobe PA USA, (subsidiary of Timken) | |

| T5 | Super Panther | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA |

T6 typical analysis (%): C 0.8; W 20.0; Cr 4.0; V 2.0; Co 12.0; Mo 0.8 – a high cobalt steel having the highest red hardness of any tool steel. Wear resistance is better than the lower cobalt steels.

Suitable for heavy-duty lathe and planer tools.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T6 | A C X | Atlas Steels Ltd, Welland, Ontario, Canada | For high cutting edge temperature |

| T6 | B.1 | Comsteel, Australia | |

| T6 | Bonded Carbide Sr | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T6 | Electrite Ultra Cobalt | Latrobe Steel Co, Latrobe PA USA | |

| T6 | Electrite Ultra Cobalt XL | Latrobe Steel Co, Latrobe PA USA | |

| T6 | Grey Cut Cobalt | Vanadium Alloys Steel Co / Teledyne Vasco, Latrobe PA USA | |

| T6 | Halcomb 440 | (?) | Maker unknown |

| T6 | King Cobalt | Jessop Steel Co, Washington PA USA | |

| T6 | Rex 440 | Crucible Specialty Metals, NY USA | |

| T6 | Stag Extra Special | Balfour Darwins Ltd, Sheffield, England | |

| T6 | Stag Major | Balfour Darwins Ltd, Sheffield, England | |

| T6 | Ultra Capital 22 | Arthur Balfour & Co Ltd / Eagle & Globe Steel Co Ltd, Sheffield / Darwins Alloy Castings | |

| T6 | Ultra Capital Plus 2 | Arthur Balfour & Co Ltd / Eagle & Globe Steel Co Ltd, Sheffield | C 0.75; Cr 4.2; W 20.0; V 1.5 and Co 10.0 |

| T6 | Ultra Cobalt | Latrobe Steel Co, Latrobe PA USA, | |

| T6 | Usaspead Cobalt 10 | Macready’s Metal Co Ltd, London, England | W 22; Co 12 |

T7 typical analysis (%): C 0.7; W 14.0; Cr 4.0; V 2.0 – lowered tungsten content gives increased toughness with less wear resistance.

Suitable for intermittent cutting and for sand castings, hard alloys or gritty materials.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T7 | Electrite Uranium | Latrobe Steel Co, Latrobe PA USA | |

| T7 | Electrite UXL | Latrobe Steel Co, Latrobe PA USA | |

| T7 | Extra Special HS | Bethlehem Steel Co, Bethlehem PA USA | |

| T7 | Gyro | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T7 | Rex Champion | Crucible Specialty Metals, NY USA | |

| T7 | Star Blue Chip | Firth Sterling Inc, Pittsburgh PA USA |

T8 typical analysis (%): C 0.8; W 14.0; Cr 4.0; V 2.0; Co 5.0; Mo 0.8 – wear resistance exceeded only by T3 combined with good red hardness make this steel suitable for severe cutting operations, especially stainless steels. It has also given good results on hard die blocks, manganese steel castings and chilled cast iron.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T8 | B8 | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| T8 | Electrite UB | Latrobe Steel Co, Latrobe PA USA | |

| T8 | Electrite UB XL | Latrobe Steel Co, Latrobe PA USA | |

| T8 | FS 2-5 | Firth Sterling Inc, Pittsburgh PA USA | |

| T8 | Gold Star | Carpenter Steel Co, Reading PA USA | |

| T8 | Maxite | Columbia Tool Steel Co, Columbia IL USA | |

| T8 | No.14 | Houghton & Richards Inc, Boston MA USA | |

| T8 | Rex 95 | Crucible Specialty Metals Co, NY USA | Outstanding tool bit for general purpose applications Co 5.25 |

| T8 | Rex Champion | Crucible Specialty Metals Co, NY USA | |

| T8 | SaBeN | Sanderson Kayser Ltd, | |

| T8 | Super Rapid Extra 500 | Bohler Edelstahl GmbH | |

| T8 | T-8 | Jessop Steel Co, Washington PA USA |

T9 typical analysis (%): C 1.25; W 18.5; Cr 4.0; V 4.0; Mo 0.75 – a high vanadium steel for extremely abrasive conditions. Runs best at high speeds with light cuts.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T9 | Carvite | Columbia Tool Steel Co, Columbia IL USA | No longer in common use |

| T9 | Rex 4V | Crucible Specialty Metals Co, NY USA | No longer in common use |

T12 typical analysis (%): C 1.0; W 14.0; Cr 4.0; V 3.0; Mo 0.75 – a tough high speed steel designed for high resistance to impact. Suitable for variable cutting, such as turning through scale and broaching.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T12 | Rex 3-V | Crucible Specialty Metals Co, NY USA |

T15 typical analysis (%): C 1.5; W 13.0; Cr 4.25; V 5.0; Co 5.0 - a tungsten super high speed steel containing high vanadium for excellent abrasion resistance and cobalt for good red hardness. Ideal for cutting difficult to machine materials where high frictional heat is present. Typical applications include broaches, milling cutters, spade drills, taps, end mills, shaper cutters.

T15 Powder Metallurgy (PM) is a tungsten high-speed steel designed for use in machining operations requiring heavy cuts, high speeds and feeds. Its primary use is in applications requiring the machining of high-hardness heat-treated materials such as high temperature alloys. The high carbon, vanadium, and cobalt contents contribute to good wear resistance, hot hardness and good hardness capabilities. T15 PM is produced by the powder metallurgy process which has resulted in improved quality from the standpoint of structural uniformity, response to heat treatment and grindability. These factors, along with increased toughness, are increased usage in the industry because of its recognized superior cutting ability.

Typical applications include roaches, chasers, form tools, heavy duty cutting tools, high production blades, milling cutters, reamers, and taps.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| T15 | ASP2015 | Erasteel, France | High performance powder metallurgy grade |

| T15 | CPM Rex T15 | Crucible Specialty Metals Co, NY USA | Made by the Crucible Particle Metallurgy (CPM) process - ideal for cutting difficult materials where high frictional heating is encountered |

| T15 | Cyclops T15 | Cytemp Specialty Steels Division, USA | Now Cap T-15 obsolete |

| T15 | Darwin 5V | Darwin & Milner Inc, Cleveland OH USA | Co 5.0 |

| T15 | DoAll T-15 | DoAll Co, Des Plaines IL USA | |

| T15 | DuraTech T15 | Latrobe Specialty Steels Co, USA | Powder metallurgy (PM) microstructure |

| T15 | Dynavan | Latrobe Specialty Steels Co / Timken Latrobe Steel | Super HSS designed for extra-high wear resistance and superior hot hardness |

| T15 | Electrite Dynavan X-L | Latrobe Steel Co, Latrobe PA USA | Co 5.0 |

| T15 | Maxite 15 | Columbia Tool Steel Co, Columbia IL USA | |

| T15 | No.445 | Houghton & Richards Inc, Boston MA USA | |

| T15 | Panther 5 | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | Cobalt HSS |

| T15 | Red Sabre | Bethlehem Steel Co, Bethlehem PA USA | |

| T15 | Rex T15 | Crucible Specialty Metals Co, NY USA | |

| T15 | Rex T15S | Crucible Specialty Metals Co, NY USA | |

| T15 | T-15 | Braeburn Alloy Steel Co, Braeburn PA USA | |

| T15 | T-15 | Carpenter Steel Co, Reading PA USA | |

| T15 | T-15 | Jessop Steel Co, Washington PA USA | |

| T15 | T-15 | Ziv Steel & Wire Co, USA | |

| T15 | Tunco C | Simonds Saw & Steel Co, Lockport NY USA | |

| T15 | Vasco Supreme | Teledyne Vasco, Latrobe PA USA / Vanadium Alloys Steel Co, Latrobe PA USA | Cobalt HSS |

TYPE “M” Molybdenum-Rich HSS

M1 typical analysis (%): C 0.8; W 1.5; Cr 4.0; V 1.0; Mo 8.25 – the high-molybdenum, low-tungsten HSS which is typically used is for cutting tools of all kinds. It has good cutting ability except for heavy-duty continuous cutting operations where the ultimate in red hardness is required.

Due to its high molybdenum content M1 is susceptible to decarburisation at high temperatures, consequently in heat treating and heating for forging and annealing care must be used to prevent decarburisation.

Both toughness and wear resistance are slightly better than T1.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M1 | 8-N-2 | Teledyne Vasco, Latrobe PA USA | |

| M1 | BM09 | (?) | Maker unknown |

| M1 | Bohler S401 | Bohler-Uddeholm | For taps, twist drills, reamers, milling tools, broaches tools |

| M1 | Di-Mol | Henry Disston & Sons Inc, Philadelphia PA USA | |

| M1 | Electrite Tatmo XL | Latrobe Steel Co, Latrobe PA USA | |

| M1 | Fagersta D-943 | Fagersta Stainless AB, Sweden | |

| M1 | Gorham HS M1D | Gorham Tool Industries Inc, Detroit MI USA | |

| M1 | Hi-Mo or Hi Mo | Firth Sterling Inc, Pittsburgh PA USA / Teledyne Cutting Tool | |

| M1 | HM or HM HS | Bethlehem Steel Co, Bethlehem PA USA | |

| M1 | LMW | Allegheny Ludlum Steel Corp, Pittsburgh PA USA | |

| M1 | Lo-S 2246 | Lohmann | |

| M1 | M-1 | Bethlehem Steel Co, Bethlehem PA USA | |

| M1 | M1 High Speed | Achorn Steel Co., Boston MA USA | |

| M1 | M-M-1 | A Milne & Co, New York NY USA | |

| M1 | Mo-Cut or Mocut | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M1 | Mogul | Jessop Steel Co, Washington PA USA | |

| M1 | Mohican | Atlas Steels Ltd, Welland, Ontario, Canada | General purpose |

| M1 | Molite 1 | Columbia Tool Steel Co, Columbia IL USA | |

| M1 | Molite M1 | Columbia Tool Steel Co, Columbia IL USA | |

| M1 | Molyhi | Houghton & Richards Inc, Boston MA USA | |

| M1 | Mo-Max | Cleveland Twist Drill Co, Cleveland OH USA | |

| M1 | Mo-Tung or Motung | Universal Cyclops, Cytemp Specialty Steels Division, USA | |

| M1 | Rex TMO or T-Mo | Crucible Specialty Metals, NY USA | Adapted to fast light cuts on soft or medium hard materials |

| M1 | Rex TMO-S | Crucible Specialty Metals, NY USA | |

| M1 | S401 | (?) | Maker unknown |

| M1 | Star Max | Carpenter Steel Co, Reading PA USA | |

| M1 | STM | Simonds Saw & Steel Co, Lockport NY USA | C0 3.0 – 8.0 |

| M1 | Tatmo | Latrobe Steel Co, Latrobe PA USA / Timken Latrobe Steel | |

| M1 | TMC | Jessop Steel Co, Washington PA USA |

M2 typical analysis (%): C 0.8; W 6.0; Cr 4.0; V 2.0; Mo 5.0 - a tungsten molybdenum, general purpose grade which offers balanced shock-resistance and high toughness combined with good cutting powers. Suited for general machining of carbon, alloy and tool steel types. Offers good heat and abrasion characteristics. Standard machining operations can be carried out with M2 high speed steel tool bits. Bits are supplied hardened to approximately 62 to 66HRc.

M2 is by far the most popular high speed steel replacing T1 in most applications because of its superior properties and relative economy in general purpose cutting and non-cutting applications. A higher carbon content and balanced analysis produce properties applicable to all general-purpose high-speed uses. It has a wider heat-treating range than most of the molybdenum high-speed steels, coupled with a resistance to decarburization that is characteristic of tungsten types. M2 offers an excellent combination of red hardness, toughness, and wear resistance.

Typical applications include gear cutters, broaches, boring tools, chasers, drills, end mills, form tools, hobs, lathe and planer tools, punches, taps, reamers, and saws.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M2 | 66 or 66HS | Bethlehem Steel Co, Bethlehem PA USA | |

| M2 | 6-6-2 | (?) | Maker unknown |

| M2 | 6N6 or 6N6M-2 | Henry Disston & Sons Inc, Philadelphia PA USA | |

| M2 | A.5 | Comsteel, Australia | General purpose HSS |

| M2 | Alpha 2 | Akers | |

| M2 | Bethlehem M-2 | Bethlehem Steel Co, Bethlehem PA USA | |

| M2 | Bohler S601 | Bohler-Uddeholm | Taps, twist drills, reamers, broaching tools, metal saws, milling tools, wood working tools, cold work tools |

| M2 | Braemow or Braemow M-2 | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M2 | Capital 5-6-2 | Eagle & Globe Steel / Balfour & Darwins, Sheffield, England | |

| M2 | CPM Rex M2 | Crucible Specialty Metals, NY USA | |

| M2 | Cyclone 92 | Samuel Osborn & Co, Sheffield England | |

| M2 | DBL-2 | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech Specialty Steel Corp. USA | |

| M2 | Double Six | Latrobe Specialty Steels Co / Timken Latrobe Steel, USA | |

| M2 | Dreadnought M-2 | Hawkridge Brothers Co, Boston MA USA | |

| M2 | Electrite Double Six XL or M-2 XL | Latrobe Specialty Steels Co, Latrobe PA USA | |

| M2 | Gorham M2R | Gorham Tool Industries Inc, Detroit MI USA | |

| M2 | H51 | Nippon Koukan Steel Co Ltd | |

| M2 | HM2 | Nachi-Fujikoshi Corp, Japan | |

| M2 | HS-29XL | Latrobe Specialty Steels Co, Latrobe PA USA / Bohler-Uddeholm | M2 composition with the carbon content increased and with the addition of alloy sulphides |

| M2 | KENROK HSS M-2 | (?) | Maker unknown |

| M2 | M-2 | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M2 | M-2 or Rex M2 | Crucible Specialty Metals, NY USA | |

| M2 | Mo5 | Schmidt & Clemens, Frankfurt Germany | |

| M2 | Mo-Max | Cleveland Twist Drill Co, Cleveland OH USA | |

| M2 | Molite M2 | Columbia Tool Steel Co, Columbia IL USA | |

| M2 | Molite-2 | Columbia Tool Steel Co, Columbia IL USA | |

| M2 | Molite-2 Smoothcut | Columbia Tool Steel Co, Columbia IL USA | |

| M2 | Molva-T | Simonds Saw & Steel Co, Lockport NY USA | |

| M2 | Mo-Tung 652 or Motung 652 | Universal Cyclops, Cytemp Specialty Steel Division, USA | |

| M2 | Mushet MKK | Samuel Osborn & Co, Sheffield England | |

| M2 | Mustang | Jessop Steel Co, Washington PA USA | |

| M2 | No.57 | Houghton & Richards Inc, Boston MA USA | |

| M2 | QH51 | Sanyo Special Steel Co ltd | |

| M2 | Red Shadow | Ziv Steel & Wire Co, USA | |

| M2 | Rex M2 or M-2 | Crucible Specialty Metals Co, NY USA | Suitable for a variety of cutting tools and often used for metal forming tools such as punches and dies |

| M2 | Rex M2 or M2S (high carbon) | Crucible Specialty Metals Co, NY USA | C 0.98 |

| M2 | Rex M25 | Crucible Specialty Metals Co, NY USA | |

| M2 | Rex M2S (1.0C) High Carbon | Crucible Specialty Metals Co, NY USA | Better hardenability in larger tool sections |

| M2 | Rex M2-S or M2S | Crucible Specialty Metals Co, NY USA | C 0.85 |

| M2 | Sixix | Atlas Steels Ltd, Welland Ontario Canada | General purpose |

| M2 | SKH9 | Nachi-Fujikoshi Corp, Japan | |

| M2 | Speed Star | Carpenter Steel Co, Reading PA USA | Lathe tools, planer tools, drills, taps, reamers, broaches, milling cutters, form cutters, thread chasers, end mills, gear cutters, wood knives |

| M2 | Stag Mo562 | Edgar Allen & Co, Sheffield England | |

| M2 | Star-Mo or Star-Mo M2 | Firth Sterling Inc, Pittsburgh PA USA | |

| M2 | T.E.M. (aka EM2 and TEM92 | Erasteel Inc (France and Sweden) | |

| M2 | Tecmax or Tec Max | P&N, Australia | |

| M2 | Vasco M-2 | Teledyne Vasco, Latrobe PA USA | |

| M2 | YXM1 | Hitachi Metals Ltd |

M3 typical analysis (%): C 1.0; W 6.0; Cr 4.0; V 2.75; Mo 5.0 and M3 (Class 1) typical analysis (%): C 1.05; W 6.25; Cr 4.0; V 2.5; Mo 5.7 and M3 (Class 2) typical analysis (%): C 1.2; W 5.6; Cr 4.0; V 3.25; Mo 5.5 – contains carbon and vanadium levels that are intermediate between those of M2 and M4. This gives the steel a fine balance of wear resistance and grindability and provides superior resistance to abrasion and edge breakdown. This makes M3 high speed steel a superb tool material for form tools and roll turning. Increased tool life will also be experienced in the machining of heat-treated sections, castings and similar hard materials.

M3 was developed after extensive studies of the effect of increased carbon and vanadium contents on the intermediate molybdenum-tungsten high-speed steels. The analysis was tried and proven on practically all high-speed steel applications. M3 offers the unusual combination of extremely high-edge strength at high hardness levels. With few exceptions, best life is accomplished with a minimum hardness of 65.5 Rockwell C. Experience indicates that the chemical balance achieved in M3 results in optimum combination of cutting ability, abrasion resistance, edge strength, red hardness, and long service life. M3 is more readily machined and offers less grinding resistance than higher vanadium types.

Typical applications include drills, taps, end mills, reamers, counterbores, broaches, hobs, form tools, lathe and planer tools, checking tools, milling cutters, slitting saws, punches, drawing dies, and wood working knives.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M3 (1) | Braevan | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M3 (2) | Braevan-2 | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M3 (1) | Corsair | Latrobe Steel Co, Latrobe PA USA / Timken Latrobe Steel | Form tools, spade drills, milling cutters and broaches |

| M3 (2) | Crusader | Latrobe Steel Co, Latrobe PA USA / Timken Latrobe Steel | Outstanding red hardness, edge toughness and wear resistance; good resistance to abrasion and edge breakdown. Typical applications form tools, spade drills, milling cutters and broaches |

| M3 (1) | Crusader L | Latrobe Steel Co, Latrobe PA USA | |

| M3 (2) | Crusader XL | Latrobe Steel Co, Latrobe PA USA | |

| M3 (1) | DBL-2.1/2 | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | |

| M3 (1) | DBL-3 | Allegheny Ludlum Steel Corp, Pittsburgh PA USA | |

| M3 | Dreadnaught M-3 | Hawkridge Brothers Co, Boston MA USA | |

| M3(2) | DuraTech 30 | Latrobe Specialty Steels Co, Latrobe PA USA | Super high speed steel based upon the chemical composition of ASTM M3-2 high speed steel, but with the addition of 8.0 + cobalt |

| M3 (1) | Electrite Corsair XL | Latrobe Steel Co, Latrobe PA USA / Bohler-Uddeholm | |

| M3 | Electrite Crusader | Latrobe Steel Co, Latrobe PA USA | |

| M3 (2) | Electrite Crusader XL | Bohler-Uddeholm | |

| M3 | Electrite MHV-6 | Latrobe Steel Co, Latrobe PA USA | |

| M3 (1) | FSM2-1/2 | ||

| M3 (1) | Jessop M-3-1 | Jessop Steel Co, Washington PA USA | |

| M3 (2) | Jessop M-3-2 | Jessop Steel Co, Washington PA USA | |

| M3 (1) | M2.1/2 High Speed | Achorn Steel Co, Boston MA USA | |

| M3 (1) | M-3 | Atlas Steels Ltd, Welland Ontario Canada | Most competitive to carbide |

| M3 (1) | M-3 | Jessop Steel Co, Washington PA USA | |

| M3 (2) | M3 High Speed | Achorn Steel Co, Boston MA USA | |

| M3 (2) | Molite-3 | Columbia Tool Steel Co, Columbia IL USA | |

| M3 (1) | Molite-3 and Molite 3 Smoothcut | Columbia Tool Steel Co, Columbia IL USA | |

| M3 (1) | Molva TC | Simonds Saw & Steel Co, Lockport NY USA | |

| M3 (2) | No.7 Type 1 | Houghton & Richards Inc, Boston MA USA | |

| M3 (1) | Rex M-3 or M3-1 or M3S-1 or M-3 Type 1 | Crucible Specialty Metals Co, NY USA | C 1.05 |

| M3 (2) | Rex M-3 or M3-2 or M3S-2 or M3 Type 2 | Crucible Specialty Metals Co, NY USA | C 1.2 |

| M3 (1) | Super Speed Star | Carpenter Steel Co, Reading PA USA | |

| M3 (1) | T.E.M.02.V | Erasteel Inc, France | |

| M3 (1) | Three Star (Class 1) | Carpenter Steel Co, Reading PA USA | |

| M3 (2) | Three Star (Class 2) | Carpenter Steel Co, Reading PA USA | |

| M3 (1) | Unicut | Universal Cyclops, Cytemp Specialty Steels Division | |

| M3 (2) | Unicut-2 | Universal Cyclops, Cytemp Specialty Steels Division | |

| M3 (1) | Van Cut Type 1 | Teledyne Vasco, Latrobe PA USA | |

| M3 (2) | Van Cut Type 2 | Teledyne Vasco, Latrobe PA USA | |

| M3 (2) | Vanadis 23 | Bohler-Uddeholm | |

| M3 (1) | Van-Chip or Van Chip | Firth Sterling Inc, Pittsburgh PA USA | 6-6-3 HSS unusually tough and durable bit for general machining |

M4 typical analysis (%): C 1.3; W 5.5; Cr 4.0; V 4.0; Mo 4.75 - a high-vanadium special purpose high speed steel exhibiting better wear resistance and toughness than M2 and M3 in cold work punches, die inserts and cutting applications involving high speed and light cuts. Used for cutting tools of all types for machining operations.

M4 Powder Metallurgy (PM) a member of the molybdenum-tungsten family of high-speed steels, is a special purpose grade which utilizes its higher carbon and vanadium contents to develop excellent abrasion resistance. Produced conventionally, M4 is difficult to machine in the annealed condition and grind in the hardened condition. M4 PM is produced by the powder metallurgy process and allows an addition of 0.06 to 0.08 sulphur which provides a uniform dispersion of small sulphides throughout the structure and enhances machinability. Coupled with finer carbides and structural uniformity, better grindability is also achieved. These factors, along with increased toughness, are ideally suited for heavy-duty cold-work applications.

Typical applications include blades, broaches, chasers, die inserts, form tools, lathe and planer tools, milling cutters, punches, reamers, slitter knives, spade drills, and taps.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M4 | Atlas M-4 | Atlas Steels Ltd, Welland Ontario Canada | |

| M4 | Bohler S692/S693 Microclean | Bohler-Uddeholm | Made using powder metallurgy - premium milling cutters, broaches and shaper cutters, taps and reamers, circular and dovetail form tools |

| M4 | Braefour | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M4 | CPM Rex M4 | Crucible Specialty Metals Co, NY USA | |

| M4 | Cyclops M-4 | Universal Cyclops, Cytemp Specialty Steels Division | |

| M4 | DBL-4 | ||

| M4 | DuraTech | Timken Latrobe Steel, USA (now Latrobe Specialty Steels Co) | Powder metallurgy (PM) microstructure |

| M4 | Four Star | Carpenter Steel Co, Reading PA USA | Lathe tools, planer tools, drills, taps, reamers, broaches, milling cutters, form cutters, thread chasers, hobs, counterbores |

| M4 | No.7 | Houghton & Richards Inc, Boston MA USA | |

| M4 | Jessop M-4 | Jessop Steel Co, Washington PA USA | |

| M4 | M4 High Speed | Achorn Steel Co, Boston MA USA | |

| M4 | Molite 42 | ||

| M4 | Molite-4 | Columbia Tool Steel Co, Columbia IL USA | |

| M4 | Neatro | Teledyne Vasco, Latrobe PA USA | |

| M4 | Rex M4 | Crucible Specialty Metals, NY USA | Gives maximum performance working with abrasive materials |

| M4 | Stark | Latrobe Steel Co, Latrobe PA USA / Timken Latrobe Steel | Form tools, spade drills, end mills, taps and dies, punches and broach inserts |

| M4 | Ultra Capital 395 | Arthur Balfour & Co Ltd / Eagle & Globe Steel Co Ltd, Sheffield England | C 1.25; Cr 4.5; W 5.5; V 4.0 and Mo 4.5 - combines high wear resistance with toughness |

M6 typical analysis (%): C 0.8; W 4.0; Cr 4.0; V 1.5; Co 12.0; Mo 5.0 – has high red hardness and properties similar to T6. Suitable for cutting hard materials and heat-treated forgings. Operates at higher speeds and feeds than regular high speed steels.

Suitable for cutting hard materials and heat-treated castings. Operates at higher speeds and feeds than regular high speed steels.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M6 | Congon or Congo? | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M6 | Electrite CO-12 | Latrobe Steel Co, Latrobe PA USA (a subsidiary of Timken) | Very good red hardness for lathe tools |

M7 typical analysis (%): C 1.0; W 1.75; Cr 3.75; V 2.0; Mo 8.75 - widely used for cutting tools in machining operations. Exhibits good abrasion resistance because of its carbon and vanadium contents. It is an excellent choice for premium tools which require an outstanding balance of red hardness, edge toughness, and wear resistance. It is especially suited for machining semi-hard, heat-treated steel at about 300-350 Brinell hardness.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M7 | Bethlehem M-7 | Bethlehem Steel Co, Bethlehem PA USA | |

| M7 | Bohler S400 | Bohler-Uddeholm | Taps, twist drills, reamers, milling tools, broaches tools, cold extrusion dies |

| M7 | Electrite Tatmo-V | ||

| M7 | EM7 | Erasteel, France | |

| M7 | Fagersta D-954 | Fagersta Stainless AB, Sweden | Mo 8.8 |

| M7 | HM7 | Nachi-Fujikoshi Corp, Japan | |

| M7 | Jessop M-7 | Jessop Steel Co, Washington PA USA | |

| M7 | LMW-V | Al Tech, USA | |

| M7 | M7 | Houghton & Richards Inc, Boston MA USA | |

| M7 | Molva-C | Simonds Saw & Steel Co, Lockport NY USA / Wallace Murray Corp | |

| M7 | Mo-Max | Acme-Cleveland / Greenfield Industries USA | |

| M7 | Motuf | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M7 | Mo-Tung CV or Motung CV | Universal Cyclops, Cytemp Specialty Steels Division USA | |

| M7 | Rex M7 | Crucible Specialty Metals, NY USA | C 1.0 |

| M7 | Rex M7N | Crucible Steel Co of America, Pittsburgh PA USA | |

| M7 | Seven Star | Carpenter Steel Co, Reading PA USA | |

| M7 | Tatmo-V | Latrobe Steel Co, Latrobe PA USA | Machining of semi-hard, heat treated steel parts |

| M7 | Tatmo-VN | Latrobe Steel Co, Latrobe PA USA / Timken Latrobe Steel | Twist drills, taps, end mills, reamers and milling cutters |

| M7 | Vasco M-7 | Teledyne Vasco, Latrobe PA USA |

M8 typical analysis (%): C 0.8; W 5.0; Cr 4.0; V 1.5; Mo 5.0; Nb 1.25 – a niobium (formerly known as columbium) bearing high speed steel with unusually high wear resistance. For general-purpose cutting. Resists decarburisation in hardening.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M8 | Star Columbium | Carpenter Steel Co, Reading PA USA | Nb 1.25 |

M10 typical analysis (%): C 0.85; Cr 4.0; V 2.0; Mo 8.0 – one of the high-molybdenum types of HSS it contains chrome and vanadium but is tungsten-free. A general purpose HSS employed in tooling applications requiring excellent wear and cutting capabilities including punches, taps, drills, broaches, lathe tools, shaper tools, planer tools, etc. May also be used for boring tools, countersinks and reamers.

Due to its high molybdenum content M10 is susceptible to decarburisation at high temperatures, consequently in heat treating and heating for forging and annealing care must be used to prevent decarburisation.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M10 | Bethlehem M-10 | Bethlehem Steel Co, Bethlehem PA USA | |

| M10 | Electrite TNW XL | Latrobe Steel Co, Latrobe PA USA | |

| M10 | Fagersta D-960 also Fagersta FB-M10 | Fagersta Stainless AB, Sweden | |

| M10 | FMP 948 | F M Parkin Ltd, Sheffield England | Mo 8.25 |

| M10 | FSM-10 | Firth Sterling Inc, Pittsburgh PA USA | |

| M10 | HS-12 | Latrobe Steel Co, Latrobe PA USA | Mo 8.0 – 11.0 |

| M10 | M-10 | Bethlehem Steel Co, Bethlehem PA USA | |

| M10 | M-10 | Jessop Steel Co, Washington PA USA | |

| M10 | M10 High Speed | Achorn Steel Co, Boston MA USA | |

| M10 | MO 81 | Erasteel | Mo 8.5 |

| M10 | Molva | Simonds Saw & Steel Co, Lockport NY USA | |

| M10 | Moly Van | Houghton & Richards Inc, Boston MA USA | |

| M10 | Motemp | ||

| M10 | Movan or Mo-Van | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| M10 | Rex VM | Crucible Specialty Metals, NY USA | C 0.9 |

| M10 | Rex VM (high carbon) | Crucible Specialty Metals, NY USA | C 1.0 |

| M10 | Rex VM-S | Crucible Specialty Metals, NY USA | Mo 8.0 |

| M10 | Ten Star | Carpenter Steel Co, Reading PA USA | |

| M10 | TNW | Latrobe Steel Co, Latrobe PA USA / Timken Latrobe Steel | For punches and other tools needing high hardness and wear resistance |

| M10 | UNAMO 10 | UN Alloy Steel Corp | Mo 8.0 |

| M10 | Van-Lom | Teledyne Vasco, Latrobe PA USA | Mo 8.0 - 8.5 |

| M10 | VLM | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | |

| M10 | VM | Crucible Specialty Metals, NY USA |

M15 typical analysis (%): C 1.5; W 6.5; Cr 4.0; V 5.0; Co 5.0; Mo 3.5 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M15 | Como | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M15 | Electrite Ultravan XL | Latrobe Steel Co, Latrobe PA USA | |

| M15 | FMP 536 | F M Parkin Ltd | |

| M15 | Mushet Special VG | Samuel Osborn & Co, Sheffield England | |

| M15 | Super Unicut | ||

| M15 | T.E.M.C V | Erasteel Inc, France | Mo 5 |

| M15 | Ultravan | Latrobe Steel Co, Latrobe PA USA | |

| M15 | Vasco Supreme A | Teledyne Vasco, Latrobe PA USA | |

| M15 | Vasco Tuf | Teledyne Vasco, Latrobe PA USA |

M20 typical analysis (%): C 0.6; W 4.0; Cr 5.0; V 1.25; Co 2.5; Mo 8.0; Boron 0.25 – an economical HSS suitable for taps, threading dies, form tools and broaches.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M20 | Mo-Chip | Firth Sterling Inc, Pittsburgh PA USA |

M30 typical analysis (%): C 0.8; W 2.0; Cr 4.0; V 1.25; Co 5.0; Mo 8.0 – high red hardness and wear resistance with loss of toughness. Recommended for turning chilled iron, locomotive tyres, and heat-treated forgings and castings. Subject to decarburisation.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M30 | 8-N-2 Cobalt | Teledyne Vasco, Latrobe PA USA | Co 5.0 |

| M30 | Amotun | Atlantic Steel Co | |

| M30 | Como | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M30 | Covan | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M30 | Electrite Lacomo | Latrobe Steel Co, Latrobe PA USA | |

| M30 | Electrite Lacomo XL | Latrobe Steel Co, Latrobe PA USA | |

| M30 | FMP 530 | F M Parkin Ltd, Sheffield England | |

| M30 | Lacomo | Latrobe Steel Co, Latrobe PA USA | |

| M30 | Mo-Max Cobalt | Cleveland Twist Drill Co, Cleveland OH USA | |

| M30 | No.48 | Houghton & Richards Inc, Boston MA USA | |

| M30 | Rex TMO-5 | Crucible Specialty Metals, NY USA | |

| M30 | Super Hi-Mo | Firth Sterling Inc, Pittsburgh PA USA | |

| M30 | Super LMW | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | |

| M30 | Super Molyhi | Houghton & Richards Inc, Boston MA USA | |

| M30 | Super Mo-Tung | Universal Cyclops, Cytemp Specialty Steels Division |

M33 typical analysis (%): C 0.9; W 1.75; Cr 3.75; V 1.0; Co 8.25; Mo 9.25 - typically used for cutting tools of all kinds.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M33 | 8-N-2 Cobalt 8 | Teledyne Vasco, Latrobe PA USA | |

| M33 | Braeburn M33 | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M33 | Electrite KELVAN | Latrobe Steel Co, Latrobe PA USA | |

| M33 | Fagersta D-933 | Fagersta Stainless AB, Sweden | |

| M33 | Kelvan | Latrobe Steel Co, Latrobe PA USA | |

| M33 | Rex M33 | Crucible Specialty Metals, NY USA | |

| M33 | STM-Co | Simonds Saw & Steel Co, Lockport NY USA | |

| M33 | Super LMW Extra | Al Tech, USA | |

| M33 | Super Motung-33 | Universal Cyclops, Cytemp Specialty Steels Division |

M34 typical analysis (%): C 0.9; W 2.0; Cr 4.0; V 2.0; Co 8.0; Mo 8.0 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M34 | 86-043 | Armstrong USA | 86 series HSS |

| M34 | Achorn M34 High Speed | Achorn Steel Co, Boston MA USA | |

| M34 | Covan | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M34 | Electrite Tatmo Cobalt | Latrobe Steel Co, Latrobe PA USA | |

| M34 | FMP 928 | F M Parkin Ltd, Sheffield England | Co 8.0 |

| M34 | Rex TMO-8 or TMO-8 | Crucible Specialty Metals, NY USA | |

| M34 | Super LMW Special | Al Tech, USA | |

| M34 | Super Motung | Universal-Cyclops Steel Corp, Bridgeville PA USA | |

| M34 | Super Motung Special | ||

| M34 | Tatmo Cobalt | Latrobe Steel Co, Latrobe PA USA | |

| M34 | Vasco M-34 | Teledyne Vasco, Latrobe PA USA | |

| M34 | YXM4 | Hitachi Metals Ltd |

M35 typical analysis (%): C 0.9; W 6.0; Cr 4.0; V 2.0; Co 5.0; Mo 5.0 - used in conditions where the demand for hot hardness is important. It is also a good quality wear resistant grade for cold work applications. Commonly used for cutting tools including broaches, milling cutters, reamers, end mills and saw blades. Also known as “5% Cobalt HSS” M35 is a development of M2 and contains 5% cobalt which gives improved hardness, wear resistance and red hardness. It may be used when cutting higher strength materials. M35 is also known as HSSE or HSS-E.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M35 | Bohler S705 | Bohler-Uddeholm | |

| M35 | Capital 398 | Eagle & Globe Steel Ltd / Arthur Balfour & Co Ltd, Sheffield, England | |

| M35 | CPM Rex M-35 | Crucible Specialty Metals Co, NY USA | Made by the Crucible Particle Metallurgy (CPM) process - ideal for cutting difficult to machine materials where high frictional heating is encountered |

| M35 | CPM Rex M35 HCHS | Crucible Specialty Metals Co, NY USA | Made by the Crucible Particle Metallurgy (CPM) process - ideal for cutting difficult to machine materials where high frictional heating is encountered and for hobs and other gear cutting tools where higher red hardness is required |

| M35 | EM35 | Erasteel Inc, France | General applications |

| M35 | Forez 2AS CO | Acieries du Forez | |

| M35 | HM35 | Nachi-Fujikoshi Corp, Japan | |

| M35 | HM35 | Nippon Koukan Steel Co Ltd | |

| M35 | HS-105 | Latrobe Specialty Steels Co / Timken Latrobe Steel | Twist drills, taps, milling cutters, reamers, broaches, saws, knives, and hobs |

| M35 | Kasle KM-35 | Kasle Steel Co | |

| M35 | Komo 205 | Marathon Specialty Steels Inc | |

| M35 | Lohmann MO55 | Friedrich Lohmann GmbH | |

| M35 | Rex M2-5 | Crucible Specialty Metals, NY USA | |

| M35 | Super Star Mo | ||

| M35 | T.E.M.C | Erasteel Inc, France | |

| M35 | UNAMO 35 | UN Alloy Steel Corp | |

| M35 | Vanadis 30 | Bohler-Uddeholm | |

| M35 | VK5E | Villares |

M36 typical analysis (%): C 0.9; W 6.0; Cr 4.0; V 2.0; Co 8.0; Mo 5.0 – developed for heavy duty cutting where the maximum of red hardness is required.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M36 | Circle M | Firth Sterling Inc, Pittsburgh PA USA | |

| M36 | CO-6 | Latrobe Steel Co, Latrobe PA USA | |

| M36 | Cobalt Moly | Houghton & Richards Inc, Boston MA USA | |

| M36 | Electrite CO-6 | Latrobe Steel Co, Latrobe PA USA | |

| M36 | Electrite Co-6 XL | Bohler-Uddeholm | |

| M36 | Rex M2-5 | Crucible Steel Co of America, Pittsburgh PA USA | |

| M36 | SP PH 3690 HSSE Co5 | (?) | Maker unknown |

| M36 | Super DBL | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | |

| M36 | Victory Cobalt | Teledyne Vasco, Latrobe PA USA |

M38A typical analysis (%): C 1.5; W 6.5; Cr 4.5; V 4.75; Co 5.0; Mo 5.0 – similar to M36 but with only 5% cobalt and increased vanadium for better wear resistance.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M38A | Electrite UB-4M | Latrobe Steel Co, Latrobe PA USA |

TYPE “M” Molybdenum Ultra-Hard HSS

M40 typical analysis (%): C 0.6; W 2.0; Cr 4.0; V 2.0; Co 8.0; Mo 5.0; Boron 0.5 – more highly alloyed than M20 this steel has wear resistance said to be several times that of other high speed steels. Suitable for heat-treated steel, cast iron, brass, plastics, and other abrasive materials.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M40 | Super Mo-Chip | Firth Sterling Inc, Pittsburgh PA USA |

M41 typical analysis (%): C 1.15; W 6.25; Cr 4.25; V 2.0; Co 5.0; Mo 3.75 - a Molybdenum ultra-hard HSS whose primary application is as cutting tools for machining operations.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M41 | Bohler S705 | Bohler Edelstahl GmbH | |

| M41 | Molite 41 | Columbia Tool Steel Co, Chicago IL USA | |

| M41 | RC-70 | Jessop Steel Co, Washington PA USA | |

| M41 | Rex 49 | Crucible Specialty Metals, NY USA | C 1.1 |

| M41 | Stag Mo | Balfour Darwins Ltd, Sheffield, England | |

| M41 | T.E.M.05.C | Erasteel Inc, France |

M42 typical analysis (%): C 1.1; W 1.5; Cr 3.75; V 1.15; Co 8.0; Mo 9.5 - a molybdenum-cobalt grade with a high hardness (up to 70 Rockwell C) and superior hot hardness offering excellent cutting performance and excellent wear resistance. As an 8% cobalt high speed steel type M42 tool bits are suited for tougher materials such as work hardening types. They offer increased tool life with retention of the cutting edge. M42 tool bits are supplied hardened to approximately 65 to 68HRc. The alloy has excellent hot hardness and wear resistance and is commonly employed to machine difficult to machine materials including the superalloys.

This steel is ideal for machining higher strength materials and work hardening alloys such as stainless steels, Nimonic alloys etc. Despite its high hardness, M42 has good grindability characteristics due to lower vanadium content. The carbon content is higher than in most high-speed steels, and with this balanced composition, contributes to wear resistance and hot hardness as well as the high hardness.

Typically employed in broaches, circular and dovetail form tools, drills, end mills, lathe tools, milling cutters, punches, reamers, slitting saws, and twist drills, hobs, taps, form and gear cutters, and chasers.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M42 | ASP2042 | Erasteel, France | Powder metallurgy |

| M42 | Bohler S500 | Bohler-Uddeholm / Bohler Edelstahl GmbH | Milling cutters, taps, twist drills, broaches tools, and cold work tools |

| M42 | Bohler Super Rapid Extra 500 | Bohler-Uddeholm / Bohler Edelstahl GmbH | |

| M42 | Braemax | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M42 | Buckeye M42 | Time Steel Service Inc | |

| M42 | Capital 405 | Steelmark-Eagle & Globe, ANI Corp Ltd / Arthur Balfour & Co Ltd, Sheffield, Engalnd | |

| M42 | Cyclops 42 (M42) | Universal-Cyclops Steel Corp, Bridgeville PA USA / Cytemp Specialty Steels Div | |

| M42 | Dynamax | Latrobe Specialty Steels Co / Timken Latrobe Steel | Premium cobalt HSS designed for high hardness and superior hot hardness |

| M42 | E M42 | Erasteel Inc, France | |

| M42 | Electrite Dynamax | (?) | Maker unknown |

| M42 | Exocut | Allegheny Ludlum Steel Corp, Pittsburgh PA USA / Al Tech, USA | |

| M42 | Fagersta D-948 | Fagersta Stainless AB, Sweden | |

| M42 | Fagersta M-42 | Seco, Sweden | |

| M42 | FMP 542 | F M Parkin Ltd, Sheffield England | |

| M42 | HM42 | Nachi-Fujikoshi Corp, Japan | |

| M42 | HS 100 | Latrobe Steel Co, Latrobe PA USA | |

| M42 | HS97R | Nachi-Fujikoshi Corp, Japan | |

| M42 | Hypercut | Teledyne Vasco, Latrobe PA USA | |

| M42 | K M42 | Erasteel Inc, France | |

| M42 | Kasle KM42 | Kasle Steel Co | |

| M42 | Kelock A229 | Sanderson Kayser Ltd | |

| M42 | MH64 | Daido Steel Co Ltd | |

| M42 | Micro Melt M42 | ||

| M42 | MO 88 | Erasteel, France | |

| M42 | Molite 42 | Columbia Tool Steel Co, Chicago IL USA | |

| M42 | Rex M42 | Crucible Specialty Metals Co, NY USA | For special purpose cutting tools, with requirements beyond the capability of general purpose HSS |

| M42 | RTS CHG.D GA-417-5 M42 027 | (?) | Maker unknown |

| M42 | S500 | Bohler | |

| M42 | S500 Isorapid | Bohler | |

| M42 | Super Capital | Arthur Balfour & Co Ltd / Osborn, England | |

| M42 | Super Cle-Max Cobalt | Cleveland Twist Drill Co, Cleveland OH USA | |

| M42 | Super Mo-Max Cobalt | Cleveland Twist Drill Co, Cleveland OH USA | |

| M42 | Super Star or Superstar | Carpenter Steel Co, Reading PA USA | |

| M42 | Supermax | TEC / P&N, Australia | |

| M42 | Vasco Hypercut | Teledyne Vasco, Latrobe PA USA | Super hard HSS |

| M42 | VKM42 | Villares | |

| M42 | YXM60 | Hitachi Metals Ltd | |

| M42 | Ziv M-42 | Ziv Steel & Wire Co, USA |

M43 typical analysis (%): C 1.25; W 1.75; Cr 3.75; V 2.0; Co 8.25; Mo 8.75 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M43 | Buckeye M43 | Time Steel Service Inc | |

| M43 | Dynacut | Electrite / Latrobe Steel Co, Latrobe PA USA | Super HSS |

| M43 | FMP 929 | F M Parkin Ltd, Sheffield England | |

| M43 | Molite 43 | Columbia Tool Steel Co, Chicago IL USA |

M44 typical analysis (%): C 1.2; W 5.25; Cr 4.25; V 2.25; Co 12.0; Mo 6.25 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M44 | Braecut | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M44 | Braetuf | Braeburn Alloy Steel Co, Braeburn PA USA | Modified M44 |

| M44 | EM 44 | Electrometal SA Metals Especials | |

| M44 | T.E.M.V11 | Erasteel, France |

M46 typical analysis (%): C 1.25; W 2.0; Cr 4.0; V 3.25; Co 8.25; Mo 8.25 - primarily used for cutting tools.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M46 | Al-46 | Al Tech, USA | |

| M46 | Braeburn M46 | Braeburn Alloy Steel Co, Braeburn PA USA | |

| M46 | HS-30 | Latrobe Steel Co, Latrobe PA USA | |

| M46 | Rex M-46 | Crucible Specialty Metals, NY USA |

M47 typical analysis (%): C 1.1; W 1.5; Cr 3.75; V 1.25; Co 5.0; Mo 9.5 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M47 | Exohard | Al Tech, USA |

M48 typical analysis (%): C 1.5; W 10.0; Cr 4.0; V 3.0; Co 9.0; Mo 5.25 - a tungsten type super high speed steel hardened to RC 68-69. It contains high vanadium for excellent abrasion resistance and cobalt for excellent red hardness. Ideal for special purpose cutting tools requiring super high hardness and red hardness, excellent wear resistance and good toughness.

Typical applications include milling cutters, form tools, end mills, broaches, cutting tool inserts, reamers, extrusion die inserts, cut-off tools, lathe tools, shaper tools, and taps.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M48 | CPM Rex 76 | Crucible Specialty Steel Co, USA | A super HSS made by the Crucible Particle Metallurgy Process - outstanding for special purpose cutting tools requiring high red hardness, high abrasion resistance, and good toughness |

| M48 | DuraTech M48 | Latrobe Specialty Steels Co, USA | Powder metallurgy (PM) microstructure |

| M48 | Micro-Melt | Carpenter Steel Co, Reading PA USA | Powder metallurgy (PM) microstructure |

M50 typical analysis (%): C 0.85; Cr 4.0; V 1.0; Mo 4.25 - most often employed in tooling applications where abrasion resistance is less important, such as woodworking tools and commercial twist drills. Considered intermediate high speed steel in view of the lower total alloy content than standard types. These leaner alloy grades normally are limited to less severe service conditions.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M50 | CM-50 | Latrobe Specialty Steels Co / Timken Latrobe Steel, USA | Commercial twist drills and wood working tools, where toughness is of prime importance |

| M50 | Consumet M-50 | Carpenter Technology Corp, USA | |

| M50 | EM50 | Erasteel, France | |

| M50 | Kasle KM-50 | Kasle Steel Co | |

| M50 | Rex-50 | Crucible Specialty Metals, NY USA | |

| M50 | Rex M50 Var | Crucible Specialty Metals, NY USA |

M51 typical analysis (%): C 1.25; W 9.5; Cr 4.0; V 3.25; Co 10.0; Mo 3.5 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M51 | HSS 10%Co | Eastern | |

| M51 | SaBen TENCO | Sanderson Bros & Newbould, Sheffield | Co 10.0 |

| M51 | WKE42 or WKE-42 | Erasteel, France | Also made by Fagersta, Sweden |

M52 typical analysis (%): C 0.9; W 1.25; Cr 4.0; V 2.0; Mo 4.25 - most often employed in tooling applications where abrasion resistance is less important, such as woodworking tools and commercial twist drills. Considered an intermediate high speed steel in view of the lower total alloy content than standard types. These leaner alloy grades normally are limited to less severe service conditions.

Suited for applications not requiring a full HSS such as body stock for carbide tipped drills and reamers, wood cutters, pipe taps, thread chasers and small drills.

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M52 | Carpenter M52 | Carpenter Steel Co, Reading PA USA | |

| M52 | C.D.W | Erasteel Inc, France | |

| M52 | CM-52 | Latrobe Specialty Steels Co / Timken Latrobe Steel | Commercial twist drills and wood working tools, where toughness is of prime importance |

| M52 | E M52 | Erasteel Inc, France | |

| M52 | MV-2 | ||

| M52 | No.59 | Houghton & Richards Inc, Boston MA USA | |

| M52 | Rex-LA | Crucible Specialty Metals, NY USA | Mo 3.25 |

| M52 | Rex M-52 | Crucible Specialty Metals, NY USA | |

| M52 | Thyrapid 3392 | (?) | Maker unknown |

| M52 | Vasco M52 | Teledyne Vasco, Latrobe PA USA |

M61 typical analysis (%): C 1.8; W 12.5; Cr 4.0; V 5.0; Mo 6.5 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M61 | CPM Rex 25 | Crucible Specialty Metals, NY USA |

M62 typical analysis (%): C 1.25; W 6.25; Cr 3.75; V 2.0; Mo 10.5 -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M62 | Rex 20 | Crucible Specialty Metals, NY USA |

M100A typical analysis (%): C ?; W ?; Cr ?; V ?; Mo ? -

| HSS GRADE | MAKER’S DESIGNATION | MAKER | NOTES |

| M100A | Super Capital (?) | Arthur Balfour & Co Ltd / Eagle & Globe, England | Probably M42 |

| M100A | Ultramax | P&N, Australia | Dark gold colour - possesses a very high 'red hardness" |

COBALT-BASED ALLOYS: The Non-Ferrous Cutting Tools

Fig 10: Arthur Balfour and Co, Sheffield, U.K. - Balfalloy hard metal price list - circa 1940. |

Non-ferrous alloys used for cutting tools are often called cutting alloys. These are distinct from alloy steels, although some may contain iron and be allied to the super high speed steels. They may have a base of nickel or cobalt and usually contain tungsten.