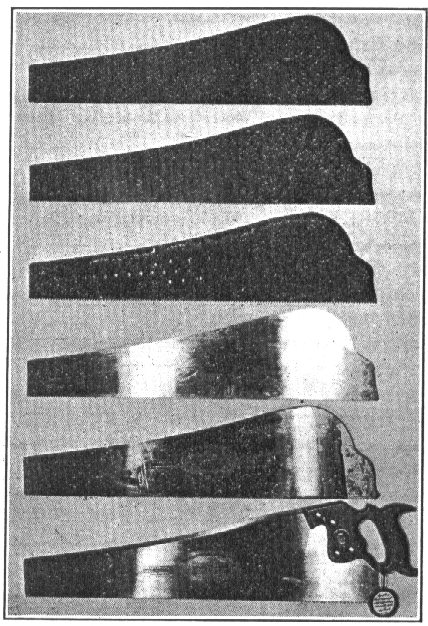

Fig 1: Stages in Making the Handsaw |

Note: This is an "orphan" article found in the TTTG archives with no information as to its original author or publication date.

Before going into the actual manufacture of a handsaw, it is as well to realise the essential qualities of a good saw. Apart from the obvious necessity of sharp teeth sharpened to the correct shape and set, it must have teeth which will retain their sharpness for as long as possible yet not be so hard that a file will not touch them ; it must have spring so that it will return to its true shape after being accidentally buckled ; its cutting edge must be under tension (for reasons explained later) ; and it must be slightly thinner at the end and back edge so that it clears easily in the kerf.

Now it would be easily possible to make a saw which would retain its sharpness for a very long time and at the same time to have a fine spring, but such a saw would be too hard for the file to cut and it would be almost impossible to set it. It is obvious then that the original making and preparation of the steel and its accurate tempering afterwards form an extremely important part of the manufacture, so that the exact compromise is produced which gives spring, and sufficient hardness to resist wear consistent with the capacity to be sharpened.

To produce these essential qualities the steel manufacturer must work in co-operation with the saw maker, and perhaps the most important part of the manufacture of the steel is in the rolling. This is done after the steel has been cast into ingots, and it must be rolled in both The length and width because the quality of the steel is affected by the direction. It has a grain (like wood only on a very much finer scale) and if rolled in one direction say the length, there would be definite long and short grain. For example, if the saw were cut out of it using the width of the sheet as the length of the blade the saw would probably have no spring and might easily break. On the oilier hon other hand, if the saw were cut with its length parallel to the length of the sheet, it would spring beautifully but the teeth would probably break off when being set. Hence the necessity for rolling in both directions.

The sheet steel having been rolled it has to be annealed (that is softened) because as it leave the rolls it would be too hard to pare to shape or tooth. This is done by heating it in a furnance and allowing it to cool slowly.

The flying-out machine is fitted with hardened dies which are driven on to the sheet steel and so strike out the shape. The first stage in Fig. l shows the blank for blade after being parted.

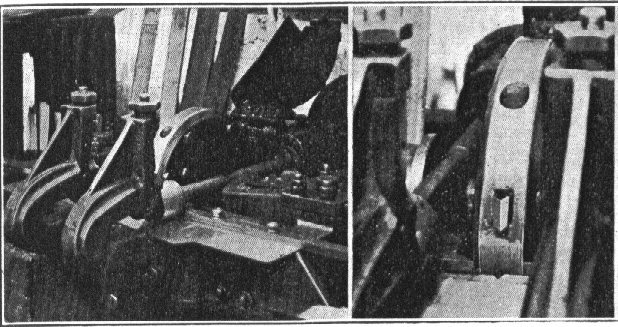

There are various types of machines for toothing a saw.

One of the quickest is the Rotary Punch which will cut abut 350 per minute. It is shown in Fig. 2. The V shaped tooth is fixed to the heavy wheel, and just passes through a V notch in the bed upon which the blade lies.

As the wheel revolves at speed it knocks out the gullet of the tooth, and the mechanism is arranged so that the blade is moved sideways immediately after the cut so that the next gullet can be formed.

The important and tricky process of hardening and tempering now follow. The blade is heated in a furnace up to the required temperature and is then quenched in oil. The exact temperature is most important because the object of hardening is to alter the structure of the crystals of the steel, and this depends upon the heat at the moment of quenching. A few degrees one way or the other make all the difference.

This hardening makes the saw so brittle that it would probably break up into many pieces if dropped, and it is necessary to temper it to remove this brittleness and to give it the springing properties. Here again considerable care and experience are required because it must be tempered uniformly. The blade is heated on a hot plate up to the required heat and then allowed to cool slowly.

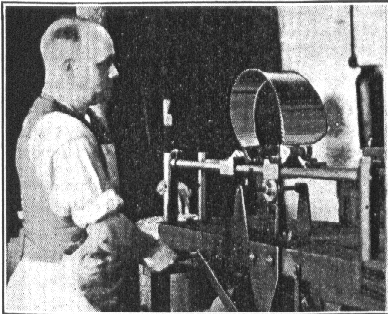

A special machine is used to test the temper. It is fitted with a small cone-shaped instrument something like a punch to look at. This is made to bear down on the saw blade at a pre-determined pressure. The extent to which the cone penetrates the steel of the blade reveals its hardness, and this is accurately registered on a meter.

Any saw which does not conform to the required standard is rejected.

The necessity for tensioning a saw is not commonly understood. The reason in that the cutting edge must always be stretched taut by the steel in the main body of the saw. If it were possible to obtain a saw absolutely fiat and free from stresses (such as the National Physical Laboratory might be able to turn out as a laboratory experiment) it would be a completely useless tool.

The Best Handsaws Are Always Set By Hand

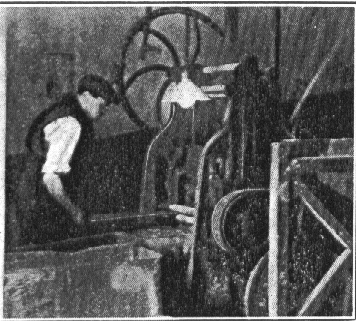

Fig 2: The toothing machine through which the blanks pass. |  Fig 3: The grinding machine |

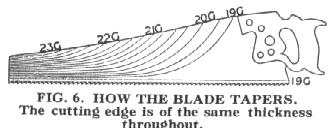

After a few strokes it would probably start binding in the cut or drifting away from the line and the user would wonder what on earth had happened. Actually what would have happened is that the small amount of heat generated on the cutting edge through friction in cutting the wood would expand that edge slightly and it would no longer be straight in consequence. On cooling it would probably become straight again, but the trouble would repeat on its being used once more The law maker knows this and by tapping the blade with a heavy hammer on a piece of flat steel he puts tension into the cutting edge which will allow for expansion. Possibly some readers have have a handsaw the edge of which was somewhat wavy, and have tried to straighten it by hammering. The probable effect of this would be to make the waves worse. A saw maker knows from experience just where to strike the blade along the centre, thereby making the cutting edge taut again The next process is that of grinding the blade because as already mentioned a good saw although of equal thickness throughout its cutting edge tapers towards the back and towards the toe. This ls made clear in the diagram in Fig 6. This taper is produced in the grinding machine shown in Fig. 3 and jt will be realized that it is a highly skilled operation because the actual amount of taper is relativety small and although the machine may run successfully for a while uneven wear on the stones may cause them to get out of condition and produce unreliable results. After being tested for accuracy the blade is polished by being passed through leather covered wheels on to which loose emery is thrown.

Any slight twists that may have occurred during the grinding are removed by blocking, a process similar to that described in tensioning.

The sharpening and setting now follow and the former is usually done on a machine. This machine does its work in almost precisely the same way that a man would do it except that the saw is moved along at each stroke of the file. Setting in the best saws is generally done by hand, and is an extremely important process. More saws are spoilt by faulty setting than by any other cause. As a rough guide approximately one third of the depth of a tooth should be bent over. Many men try to set the whole tooth, which usually ends in the tooth breaking out. The amount of set is difficult to fix exactly because, whereas little set is needed on one to be used for dry hardwoods, a saw to cut green softwood needs considerably more because the fibres tend to close after the cut. A taper ground saw needs less set than one of equal thickness throughout.

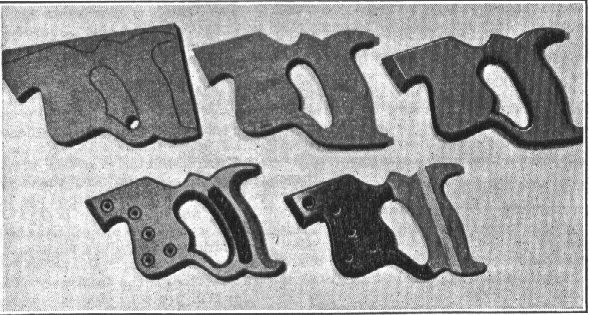

Fig4: Testing the spring. |  Fig 5: The five stages in making the handle |

A Tapered Saw is Thinner Towards the Back and Toe

Fig 6: How the blade tapers. |

All the above processes may have tended to affect the temper, and to correct this the blade is placed in a hot furnace for about ten minutes and then plunged into cold water. The makers' name has now to be put on, and this is bitten in with acid. A sort of transfer partly coated with wax in accordance with the design is placed on the blade, and an acid proof preparation is painted on to protect the rest of the blade. This the acid bites in only in the places left in the wax in the transfer.

The last job before handling is to test the blade by bending it to an acute curve, and seeing that it returns to the straight. The bending machine is shown in Fig. 4. The stages in the manufacture of the wooden handles is shown in Fig. 5. An interesting feature of the best modern type is that it is made unbreakable by the insertion of a dowel. The last stage is to grease the blade and put it in an oil paper case ready for distribution to the tool shops. (903)

We should like to acknowledge with thanks the courtesy of Messrs. Spear & Jackson, Ltd., Sheffield for allowing the writer to visit their works and take photographs of the processes, and for supplying a great deal of useful information.