The investigations by Taylor and White, which culminated in the development of ‘high speed steel’, required an exceptionally large amount of money to be spent and infinite patience to be exercised. In 1906, Taylor presented his monumental paper, “On the Art of Cutting Metals,” before the American Society of Mechanical Engineers as his presidential address. It was the result of twenty-six years of experimentation during which time more than 800,000 pounds of steel and iron were cut up into chips with experimental tools. Some 30,000 to 50,000 recorded experiments were carried out, in addition to many others not recorded.

Taylor estimated the cost of these experiments to be between $150,000 and $200,000 (see https://web.stevens.edu/libraryexhibits/FindingAids/FWT_FindingAid.html).

And we are talking about the value of the US dollar nearly 120 years ago!

But this was by no means the last word on experiments with HSS. The first public demonstration of the new ‘HSS’ in action took place at the 1900 Exposition Universelle held in Paris where the Bethlehem Steel Company of Philadelphia exhibited its products. But by 1904 the addition of vanadium had been patented by the Crucible Steel Company and this led to the formulation of what is perhaps the best-known grade, the 18-4-1 steel (later known simply as T1) in 1910. Cobalt in HSS was first reported in 1912 by Becker in Germany.

These discoveries also led to many other tool steels formerly impossible to be developed because of the relatively low hardening temperatures used beforehand. By the 1930’s there were many tool steels and high speed steels in use, demonstrating the very rapid development of steel that occurred following these important discoveries. In 1939 high-carbon high-vanadium super high-speed tool steels (M4 and Tl5) were introduced. The M40 series high-carbon high-cobalt super hard high-speed tool steels first appeared in 1961.

Since being patented by the Crucible Steel Company the composition of the T1 type or 18-4-1 HSS with 18% W (Tungsten) has not changed. Indeed, it remained the main type of HSS used in engineering workshops up until the 1940s. Today however only 5-10% of the HSS in Europe is of the T1 type and only about 2% in the USA.

The only outstanding element that has been added to the composition of HSS after its introduction by Taylor and White is vanadium. Adding vanadium increase the cutting efficiency of the HSS and also increased toughness. Its introduction appears to have first occurred around 1902.

Tungsten type HSS can be divided into two general grades according to tungsten content being those with 18% and 14% tungsten. The Super HSS or Cobalt HSS are high in tungsten, but also contain considerable quantities of cobalt. They have added red hardness but are inclined to be brittle.

Molybdenum-rich HSS

Material availability and cost also played a part in the development of HSS. Due to the shortage of tungsten and its consequent increase in price, molybdenum bearing high speed steels were introduced in the USA around 1930. Molybdenum rich HSS such as M1 has been in general use since that time and eventually gained market leadership in the USA during the 1940s.

Britain was dependent upon the molybdenum HSS during the years of World War 2 when these steels were known as ‘Substitute’ HSS. However, excessive surface decarburisation, even with the highest-grade heat treatment, was sufficient to prohibit the employment of molybdenum-type HSS for the manufacture of taps and form tools.

Molybdenum HSS was an outgrowth of an early attempt by the US Ordinance Department to substitute molybdenum for the costly and imported tungsten in HSS. The first Watertown Arsenal steel of 1940 contained about 0.8% carbon, 9.5% molybdenum, 4% chromium, 1.5% tungsten, and 1% vanadium. But the earliest known molybdenum “self-hardening” steel was the ‘MoSH’ steel made by the Sanderson Steel Company in 1898.

Many types of molybdenum HSS came onto the market in the USA. For example, ‘Motung’ high speed steel (M1) was patented by the Cleveland Twist Drill Company and contains 0.75% C, 8% Mo, 1.75% W, 4% Cr, and 1.25% V. The name ‘Mo-Tung’ is also used by the Universal-Cyclops Steel Corporation for this steel and other trade names for it include Mogul, Tatmo, Mo-Cut, Vul-Mo, Mohican, LMW, Rex T-Mo, HM Steel, and Di-Mol. Van Lom HSS by the Vanadium-Alloys Steel Company has 1% C, 9% Mo, 4.25% Cr, and 4% V. Bethlehem 66 HSS (M2) by the Bethlehem Steel Company contains 0.8% C, 5.5% W, 5% Mo, 4% Cr and 1.75% V. More often than not the product outlasted the company that made it.

The addition of about 10% of tungsten and molybdenum in total most efficiently maximises the hardness and toughness of high speed steel and maintains these properties at the high temperatures generated when cutting metals. Molybdenum has twice the effect of tungsten in terms of red hardness, but it makes the steel more brittle and also subject to decarburisation. Standard tungsten high speed steels are therefore sometimes modified with small amounts of molybdenum.

The old Damascus steel and Toledo steel were molybdenum steels, the molybdenum being in the original ore. Damascene steel refers to the wavy forging marks on blades and was not necessarily a molybdenum steel. But the original Wootz steel, or Indian steel, of this type contained small percentages of aluminium incorporated in some obscure manner. Wootz steel was made in the crucible, although the crucible method was not used in Europe until 1740.

Uses for High Speed Steel

The main use of HSS continues to be in the manufacture of various cutting tools: lathe tools, drills, taps, milling cutters, gear cutters, power saw blades, etc, although usage for punches and dies is increasing. Tool steels, and in particular HSS, can also be surface treated by nitriding, laser or plasma overlays of hard coatings (such as Stellite) as well as by chemical or physical vapour deposition of hard carbides and nitrides. This new coating technology has helped to extend the use of HSS.

While coatings, such as TiN, TiAlN or CrAlN significantly increase tool life, they also increase tool cost. Nevertheless, most tools in the higher-end applications today are coated as the higher cost is well balanced by the greater productivity during the machining processes. However, no single composition of high-speed tool steel can meet all cutting tool requirements.

The general-purpose Molybdenum steels such as M1, M2, and M7 and the Tungsten steel T1 are more commonly used than other high-speed tool steels. They have the highest toughness and good cutting ability, but they possess the lowest hot hardness and wear resistance of all the high-speed tool steels. The addition of vanadium offers the advantage of greater wear resistance and hot hardness, and steels with intermediate vanadium contents are suited for fine and roughing cuts on both hard and soft materials.

The 5% vanadium steel (TI5) is especially suited for cutting hard metals and alloys or high-strength steels, and is particularly suitable for the machining of aluminium, stainless steels, austenitic alloys, and refractory metals. Wrought high-vanadium high-speed tool steels are more difficult to grind than their particle metallurgy product counterparts.

The addition of cobalt in various amounts allows still higher hot hardness, the degree of hot hardness being proportional to the cobalt content. Although cobalt steels are more brittle than the non-cobalt types, they give better performance on hard, scaly materials that are machined with deep cuts at high speeds.

High-speed tool steels have continued to be of importance in industrial commerce for 70 to 80 years despite the inroads made by competitive cutting tool materials such as cast cobalt alloys, cemented carbides, ceramics, and cermets. The superior toughness of high speed tool steel seems to guarantee it a continuing niche in the cutting tool materials marketplace.

HSS Composition - some key elements

The essential elements of a tool steel either alone or combined with the addition of other elements is what gives each HSS grade its inherent cutting performance, red-hardness, toughness, wear-resistance, etc.

To enumerate all the wonderful qualities steel acquires when various elements are introduced in it is quite difficult. Nevertheless, here follows a summary of most of the principal alloying elements and the principal effect of each on the qualities of HSS.

NOTE: All percentages given are by weight

Aluminium (Al) – Aluminium is the most effective and frequently used deoxidiser in steelmaking. Small additions are used to ensure small grain size. It will combine with nitrogen and form hard aluminium nitrides, which is why it is added to nitriding steels.

Boron (B) - Boron is added to unalloyed and low alloyed steels to enhance the hardness level through enhancement of hardenability. Boron added to HSS, for example, containing 18% W, 4% Cr and 1% V, enhances the cutting performance, but reduces the forging qualities.

Carbon (C) - As in all tool steels, carbon is essential to the hardenability of steel. It increases tensile strength and edge retention and improves resistance to wear and abrasion. Added in isolation, it decreases toughness. Also, it is evident that, as the wearing properties and high hot hardness depend on the presence of massive amounts of complex alloy carbides, carbon is of prime importance. The usual carbon range for high speed steels is 0.65-1.5%, of which about 0.3% is dissolved in the matrix. The hardness on the finished product increases rapidly up to about 1.0% carbon. The higher carbon grades show a fairly marked fall off in ductility.

Chromium (Cr) - Added for increased wear resistance, hardness, tensile strength, and for corrosion resistance. Chromium forms large, complex carbides. A steel with at least 13% chromium is typically deemed "stainless", though another definition says the steel must have at least 11.5% free chromium (as opposed to being tied up in carbides) to be considered "stainless". Adding chromium in high amounts decreases toughness. Chromium is a carbide-former, which is why it increases wear resistance. Unfortunately, the amount of free chromium in the steels is almost never specified. Addition of 4% chromium is made to all high-speed steels with the prime purpose of promoting depth hardening. Chromium in the absence of large quantities of retained austenite sharply retards the rate of softening in these steels, but in itself does not produce a true secondary hardening peak.

Cobalt (Co) - Increases red hardness, also allows for higher quenching temperatures (during the heat treatment procedure). Intensifies the individual effects of other elements in more complex steels. Cobalt is not a carbide former, however adding cobalt to the alloy allows for higher attainable hardness and higher red-hot hardness.

Cobalt is optional as an alloy addition, being present in only a few of the "super grades" up to about 10% maximum, although a few special steels have higher additions. The addition of cobalt can raise the hardness by as much as 60HV, depending on the specific grade of steel. Its prime purpose is to promote red hardness; however, this comes at the expense of impact strength.

Lead (Pb) - Although virtually insoluble in liquid or solid steel, lead is sometimes added to carbon steels via mechanical dispersion during pouring to improve machinability.

Manganese (Mn) - An important element, manganese improves grain structure and contributes to hardenability, strength, and wear resistance. Improves the steel, deoxidises and degasifies during steel manufacture (hot working and rolling). In larger quantities, increases hardness and brittleness.

Molybdenum (Mo) - A carbide former, prevents brittleness, and maintains strength at high temperatures. Improves machinability and resistance to corrosion. Present in many high-speed steels, and air-hardening steels (e.g. A2, ATS-34) always have 1% or more molybdenum.

Nickel (Ni) - Adds toughness. Nickel is widely believed to play a role in corrosion resistance as well, but this is probably incorrect.

Niobium (Nb) formerly Columbium (Cb) - Heat treatment of the niobium-bearing steel yields fine edged carbides, which makes the steel very tough. The introduction of niobium prevents embrittlement and improves wear resistance. In small amounts, niobium can significantly increase the yield strength and, to a lesser degree, tensile strength of steels.

Tungsten (W) – Formerly known as Wolfram. Strongest carbide former after Nb and then V. Tungsten increases wear resistance. When combined properly with chromium or molybdenum, tungsten will turn a steel into a high speed steel. The M2 high-speed steel has a high amount of tungsten; around 6%.

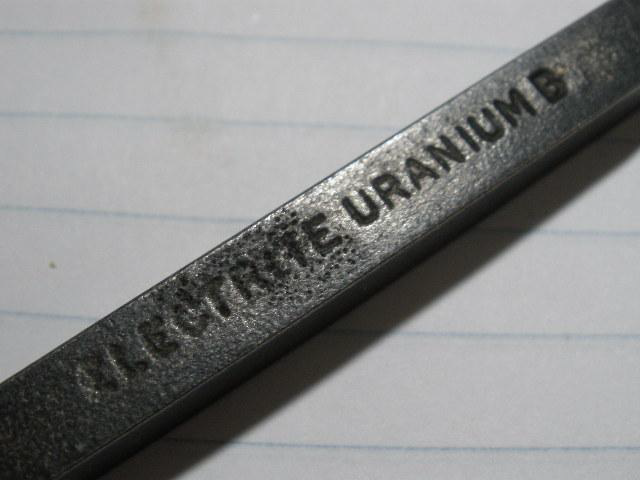

Uranium (U) – By the early 1920’s the capacity of uranium to produce types of steels with "pre-eminent capacities to resist fatigue, as far as it is possible to measure these stresses” was well recognised.

Uranium high speed steels are not embrittled by high temperatures; nor do they show a tendency to crack under severe quenching; and they are less likely to warp in heat treatment. Content of uranium is typically found to range from 0.25% up to 2.25%.

Vanadium (V) - Contributes to wear resistance and hardenability, and as a carbide former (in fact, vanadium carbides are the hardest carbides) it contributes to wear resistance. It also refines the grain of the steel, which contributes to toughness and allows the steel to take a very sharp edge.

Some steels contain just a small or moderate amount of vanadium, whereas M2, Vascowear, and CPM 10V, S90V, S125V (in order of increasing amounts) feature high amounts of vanadium. This element is always present to a minimum of 1% and generally up to 2% or 3%. It can be higher in very highly alloyed grades. Vanadium forms extremely stable carbides such as VC or V4C3, which are virtually insoluble at normal hardening temperatures, and thus create a highly effective means of limiting grain growth.

Zirconium (Zr) - The presence of zirconium compounds reduces grain coarsening, and thus permits the use of higher hardening or carburising temperatures. It produces only slight changes in the mechanical properties of quenched and tempered steels which are generally beneficial. It produces a more uniform distortion during heat treatment than other alloying elements like vanadium. In high alloys steels, it increases hardness but decreases ductility.

For the next part of the series: Tool Steels: A Brief History — Part 4 High Speed Steel Types.

For the start of the series: Tool Steels: A Brief History — Part 1 Introduction