Note: This is a classic reprint of an article from NEWS #017, June 1994.

“Here's your crow-bar and your centre bit”

W.S.Gilbert

The Pirates of Penzance

When these words were first sung in 1879, the centre bit was quite familiar to the audience of the day. In fact when the Victorian carpenter or gentleman handyman wanted to drill a reasonable size hole in a piece of timber, he invariably reached for his brace and set of centre bits.

The centre bit had been widely used since the eighteenth century both in England and on the Continent. Bergeron's "Manuel du Tourneu" of 1816 shows a centre bit amongst a range of shell augers, nose bits and spoons, although in a position of no particular prominence. Salarnan notes that in France the centre bit is sometimes called the English three-point bit which probably indicates its origin and accounts or its slower acceptance in France; national rivalry being what it is.

The centre bit had been widely used since the eighteenth century both in England and on the Continent. Bergeron's "Manuel du Tourneu" of 1816 shows a centre bit amongst a range of shell augers, nose bits and spoons, although in a position of no particular prominence. Salarnan notes that in France the centre bit is sometimes called the English three-point bit which probably indicates its origin and accounts or its slower acceptance in France; national rivalry being what it is.

Why was the centre bit so popular?

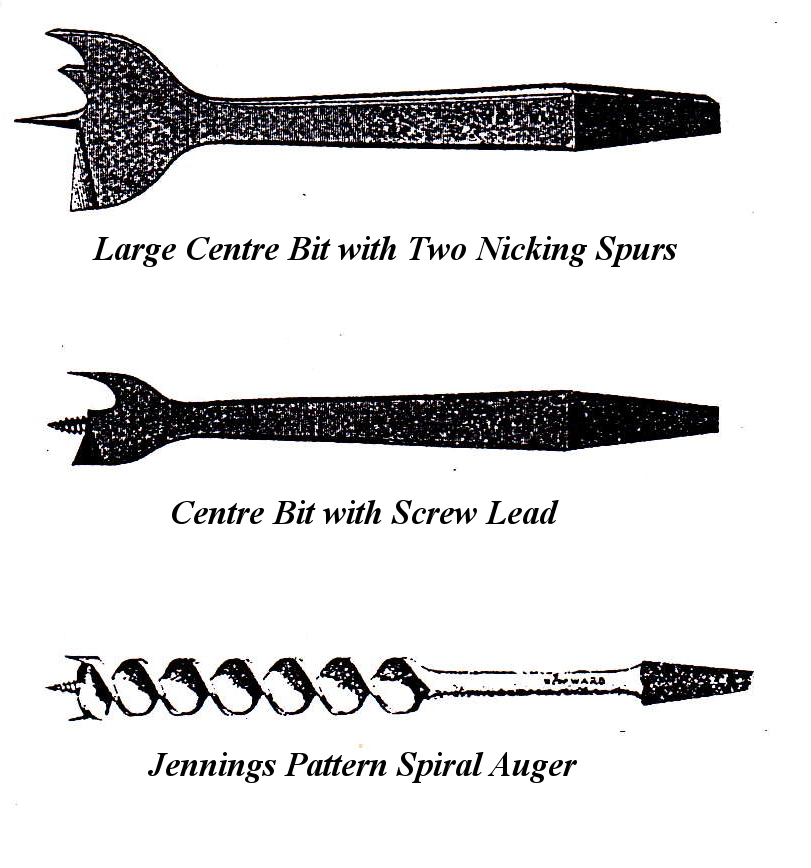

Why has it now disappeared from the tool catalogues? Although spiral or twist augers had been known for a long time, (Smith's "Key to the Various Manufactories of Sheffield", 1816, illustrates one) they were not in common use. They were expensive to make and generally made a fairly rough-edged hole as they were "Scotch" pattern without nicking spurs.

On the other hand the centre bit was extremely easy to make by small tool manufacturers. Even the local village blacksmith could turn out a centre bit which worked well. The scribing arm of the centre bit ensured that holes had cleanly cut edges even in splintery timber, the router-like single cuter produced a nearly flat-bottomed hole and the plain centre spike meant that the operator controlled the speed of cut by the amount of pressure he applied to the brace. (Later it was possible to buy centre bits with screw noses hit these were more expensive and lacked the advantage of pressure control hence they proved less popular.)

True, the centre bit did not clear the hole of shavings like the spiral augers but for shallow holes the price to performance ratio of the centre bit was unmatched.

True, the centre bit did not clear the hole of shavings like the spiral augers but for shallow holes the price to performance ratio of the centre bit was unmatched.

Centre bits were available in a large range of sizes from ¼″ to 3½″ in diameter, much larger than commonly available sizes of spiral augers. Salaman claims that for sizes over 2″ centre bits were provided with a second intermediate nicking spur but I personally have never seen one.

In 1955 Russell Jennings patented a method of manufacturing a double twist auger which was a step forward in commercialising the auger but more. importantly, he added nicking spurs to his design so that now the auger could cut holes as cleanly as the centre-bit.

Originally centre bits were designed for a button brace. Earlier ones have a notch filed in the shank for the spring catch but they fit equally as well into a modern Barber chuck and for over a century, centre bits and spiral augers coexisted in just about every woodworker's tool chest. Spiral auger remained more expensive and were used for deep straight holes whilst centre bits were used for precision boring of shallow holes.

Especially those of large diameters.

As late as 1966 Lloyd and Cowmeadow in their book “Furniture and Cabinet Making” list… “Centre bits - useful for shallow boring: available up to 2 inches.” Maybe centre bits were still available in Melbourne in 1966 (where the authors lived) but I certainly don't remember seeing them in the hardware stores in Sydney at that time.

Certainly the authors don't mention the sizes from 2″ to 3½″ with the extra spur so apparently they had already disappeared.

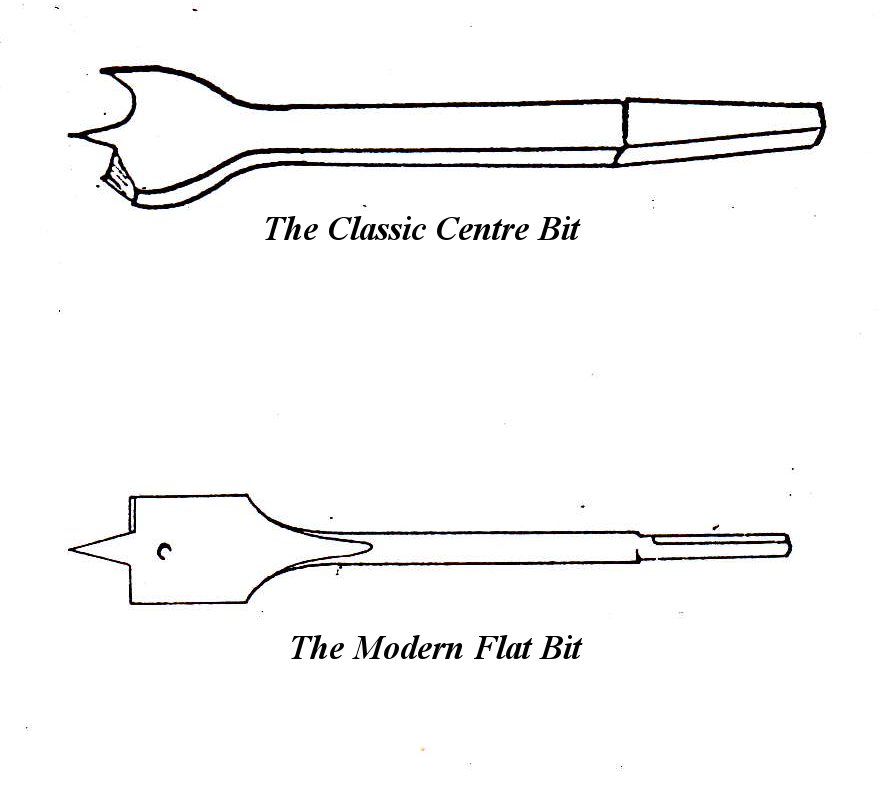

Where are they now? I suggest that the increasingly affordable electric drill displaced the smaller sizes of spiral augers and centre bits fairly rapidly during the 1950s and 60s but the brace and spiral bit held on where larger diameter deep holes were needed and the small domestic electric drill lacked the requisite torque. Enter the "Flatbit' spade-type bit which eliminated the screw lead and returned to the pointed lead of the centre bit. Now, as with the centre bit, the operator could control the rate of cut by varying the Pressure. Should the drill appear to be struggling, ease back the pressure and cut a bit slower! The flatbit usually lacks spurs but the speed of the electric drill allows a reasonably clean hole to result. The flatbit resembles the centre bit in more ways than one; it is cheap, non-chip clearing, comes in reasonably large sizes and although it has a double cutting edge, (both of which are simpler than the centre bit) it is sharpened in a similar manner.

The evolution is now clear! Today the brace is used almost exclusively with spiral auger bits and the electric drill and flatbit combination have replaced the centre bit. Or have they? When I need a clean shallow hole drilled with high precision, I still reach for my brace and collection of centre bits'