Note: This is a classic reprint of an article from NEWS #015, February 1994.

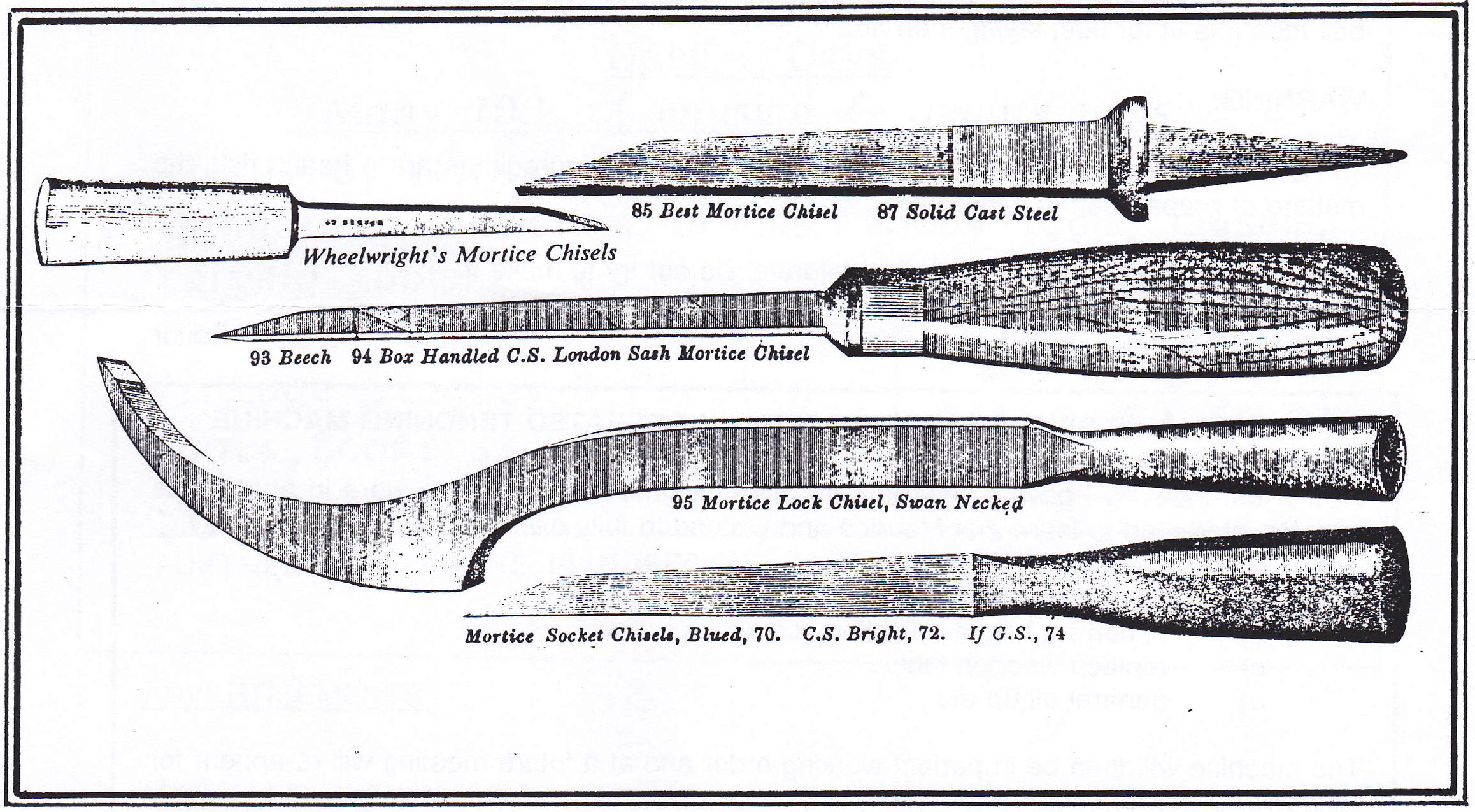

There are several types of woodworking chisels made expressly for cutting (chopping) mortises.

The Common or Joiner's Mortise Chisel

This is a heavy chisel intended for general mortising in soft or hard woods. The handle is oval and without ferrule. As with all true mortise chisels the blade is wider than it is thick and tapers in width from tang to bevel. The best quality were ground truly parallel in thickness, common quality were slightly tapered. The bulk of the blade is wrought iron with a back layer of fire welded steel. Sizes are to match standard plough irons, but the same size plough iron is always nominally thicker. As mostly these chisels were used to mortise framing or doors this was to allow panels to enter grooves freely. Common sizes used for joinery ⅜″, ½″, 9/16″. The ½″ was the most commonly used, 1¾″ doors.

Some manufacturers listed, at greater price Cabinet Mortise Chisels, these were same pattern but perhaps slightly smaller. Common cabinet size 5/16″. Sizes of both Joiner's and Cabinet from ⅛″ to 7/16″, larger sizes were listed by some makers.

Sash Mortise Chisel

A lighter chisel with turned ferrelled handle and leather tang washer. Intended to mortise sash stiles but also suitable for cabinet work. For deep mortises the Joiner's Mortise Chisel should be used. Sash mortise chisels are suitable for shallow mortises, about ½c, and soft woods. Common sizes: Joinery ⅜″, Cabinet 5/16″. Made from wrought iron laid with steel.

Special Mortise Chisels

Drawer Mortise, or bolting iron.

Small unhandled chisel used in fitting cabinet locks to drawers.

Lock Mortise Chisel (Swan-neck chisel)

Large handled chisel with curved blade. Used to clean out lock mortises when hanging panelled house doors. Cutting edge curved to

-

- cut end grain of tenons;

- lever out waste and flatten mortise bottom.

Both Sash and Lock Mortise can have beech, ash or box handles; Joiner's mortise beech or ash handles. Wrought iron "steeled".

Mortise Chisels for special trades,

e.g. Millwrights, Wheelwrights hurdle makers. These may form topic for a future article.

Modern Forms of Mortise Chisel

Improved mortise chisels were made early this century.

These include:

Socketed Mortise Chisel

Long chisel with hooped ash handle, wide tapered blade. Made in sizes ¼" to 9/16″. Not to be confused with socket firmer chisels where blade is thinner; these are not suitable for mortising.

So called Mortise Chisel, The Registered Chisel.

This is correctly the Registered Ships Chisel, a heavy firmer chisel. Some time in this century in NSW the schools were issued with this chisel. Titan-made and supplied to schools a "Registered Mortise Chisel". This chisel is totally unsuited to mortising. Yet generations of woodwork classes have been taught to use this "mortise chisel". Arguably the greatest influence on the decline of woodworking skills this century with the possible exception of the disc sander.

Use of Mortise Chisel

As with all cutting tools mortise chisels must be correctly sharpened for the work at hand. The bevel should not be too long or hollow ground. If it is so ground the steel back will be weakened and the edge will snap off with the blows used to drive the chisel into the wood. The bevel should be slightly rounded or buttressed. The back must be perfectly flat. The chisel should be struck with a mallet. For through mortises do not try to lever out the waste or core. After both sides have been chopped drive out the core with a "core driver". The sides of mortises should be carefully pared with the firmer chisel. Wedge space should be chopped last. Do not undercut sides or ends of mortises. The through mortise relies on a good fit for strength. Only glue the shoulder and wedges.

Grooves and rebates and mouldings are planed after mortising in hand work