This article by J. Geraint Jenkins of the Welsh Folk Museum, St. Fagan's Castle, Cardiff was originally published in Woodworker magazine in November 1963. It was reprinted in NEWS #149, August 2016. It is now re-published as a classic reprint for the TTTG Website.

|

Spoon carving, though a simple craft is one of great antiquity, particularly in the counties of Cardiganshire, Pembrokeshire and Carmarthenshire. In those counties, wooden spoons were widely used in the household as well as in the dairies, and although many of these spoons were the work of specialised craftsmen who combined spoon carving with the making of wooden bowels, the craft was also widely practised by amateurs.

|

From the simple art of making practical spoons, the craft of spoon carving in the nineteenth century developed into a highly artistic one. No longer were farm workers and others content with carving plain, unornamented utilitarian spoons. They developed their art to make spoonsthat were highly decorated, and which they could present to their sweetharts as tokens of love. Very often the aim of the carver was to carve a most intricate pattern out of a single piece of wood and, since the donor of the love spoon was also its maker, he tried to emphasise his love by elaborating the design as much as possible. Slotted handles, carved initials and wooden chains characterise these Welsh expressions of peasant art.

The process of making an ordinary wooden spoon, of a type still common in Welsh homes, begins with the felling of sycamore trees in the winter months. The widely occurring sycamore tree is the only one used for spoons, for it is one of the few timbers that does not leave a woody taste on food. It can be immersed in water at frequent intervals without cracking and warping, and its white lustrous sheen provides a most attractive appearance. In addition, sycamore can be scrubbed and cleaned without damaging the fibre, and above all it is one of the easiest timbers to carve.

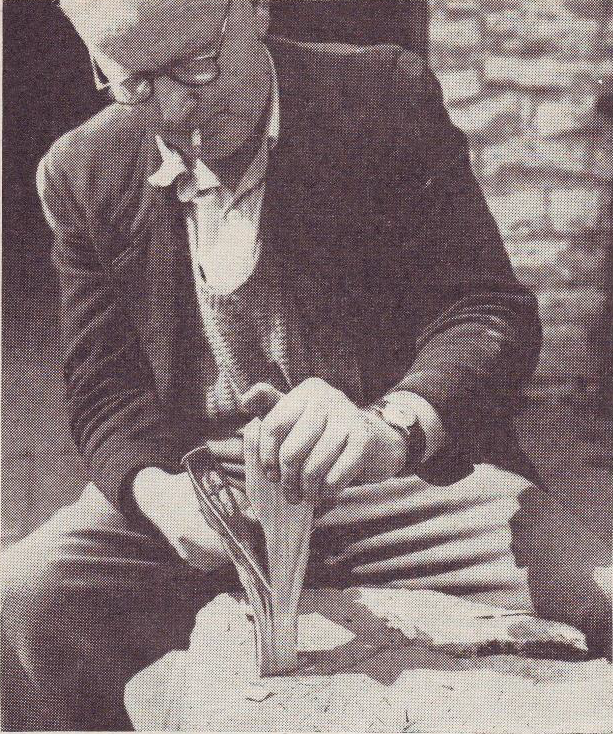

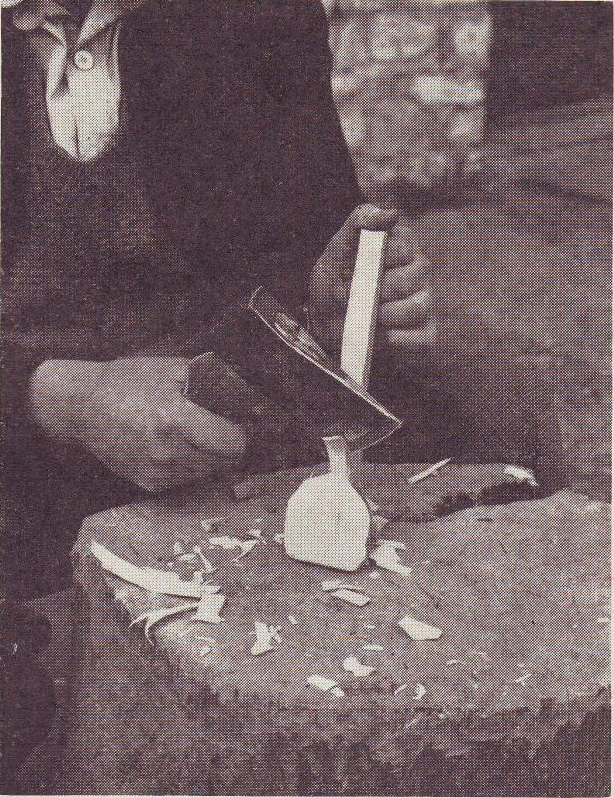

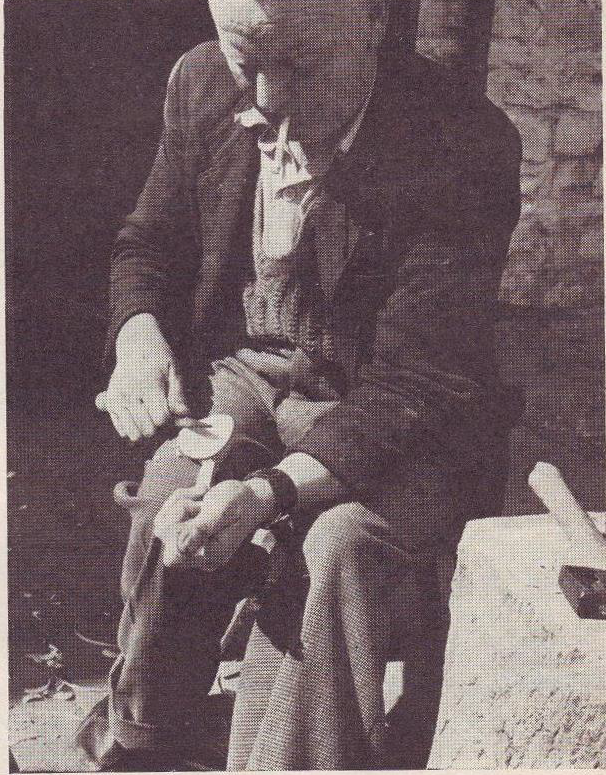

After felling the sycamore butts are cut into logs, each one some 12 inches long. With the help of a small cleaving iron and hammer each log is cut into two. The craftsman sitting on a low stool, the sycamore log is rested on a chopping block and with a short-handled axe it is cut to the approximate shape of a spoon. (Figs 1 and 2). The shouders are formed with a few deft strokes of the axe; a process that demands precision, for the shoulders have to slope away from the from the bowl at the correct angle. This first process is known as roughing out and for it nothing more than an axe is required.

|

|

The axe used is a short handled tool with a blade no more than three inches wide. Some craftsmen use a side axe, that is an axe sharpened on one side only.

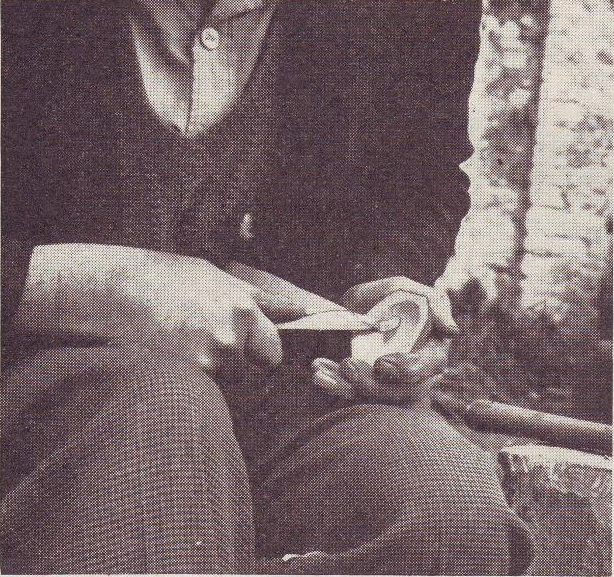

The bowl of the spoon is next hollowed out, and this is done with a home made hollowing knife (Fig 3). The knife used for making broth spoons has a handle 18 in. long with a small curved blade no more than 3 in. long. It is made from an old file and is always kept very sharp. The knife required for smoothing ladles is bigger with a blade 5 in. long. The long handle of the knife is tucked under the craftsman's arm, the blade firmly grasped with the hand and with a few sweeping actions of blade and arm the core of the bowl is removed, Considerable pressure is exerted at this stage for the core has to be removed cleanly and smoothly.

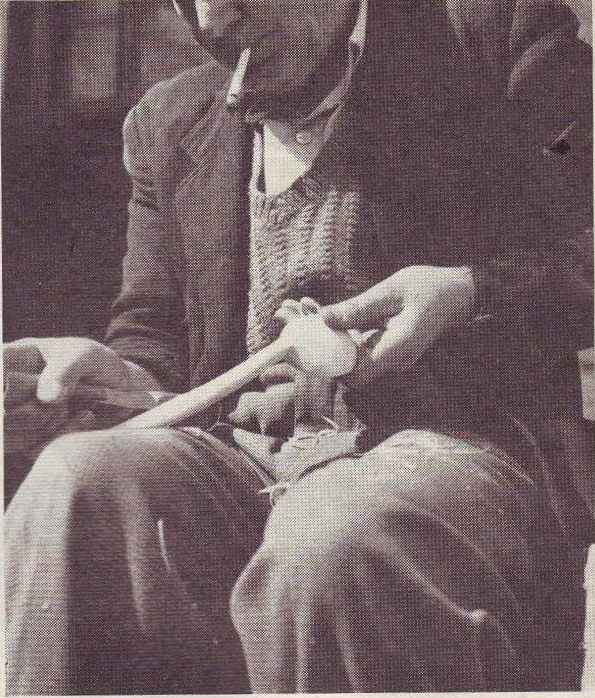

The convex side of the roughed-out spoon is next shaped. The tool for this part of the work is a small spokeshave (Fig 4) and the whole spoon finished off with a penknife (Fig 5). All that now remains is to smooth it finally with the glasspaper.

To make large ladles, which are still used in Welsh dairies as well as domestically, the process of making is rather different. In this case, slightly larger, cleft logs are required; the size depending on the type of ladle needed. Each one is roughed out in the same way as for an ordinary broth spoon, with the exception that the hook for hanging at the end of the handle has to be shaped. This hook is essential for a dairy ladle, so that it may be hung on the edge of a milk bucket, etc. The hook is shaped with the axe during roughing out.

|

|

Since the bowl of a ladle is wider and deeper than that of a broth spoon, the hollowing knife is not used to remove the core completely. Before the knife is used, therefore, the ladle is clamped in a vice at an angle of 45 degrees and a short-handled adze is used to remove the core. This adze has a 1½ in. gouge blade with a handle no more than 6 in. long and is usually made by the local blacksmith. The convex bowl is finally smoothed off with the hollowing knife. The ladle is finished in the same way as the spoon with a spokeshave and glasspaper.

Current interest in making spoons is strong and special spoon knives are again available and dedicated spoon making classes have been offered.

Back in the 1960s a bench axe, hand adze and a few crook knives were the only essentials, the roll your own smoke was an optional extra.