Note: This is a classic reprint of an article from NEWS #024, August 1995.

Screw Threads in wood require:

-

-

- a suitable timber species

- to be of V form

- to be of course pitch

-

if they are to prove efficient in use. Traditionally timbers used included beech and horn beam. For occasional use mahogany or pine was also used. In North America maple was substituted for the European preferred species.

Screw Threads were produced by various methods.

Screw Threads were produced by various methods.

- The Mandrel or Transversing Lathe

In this mechanism the head stock bearing transversed a predicable distance. In essence the motion of the mandrel moved the work piece in relation to the cutter. This was in effect the converse of the principal of the "lead screw" lathe developed in the early nineteenth century.

The Mandrel lathe is described by Moxon as being for "swash" turning, e.g. twists.

The final development of the Mandrel lathe was the Rose Engine. Such machines could cut coarse threads but it is doubtful as they were commonly used for such an application: They were too time consuming to set up for such a simple task.

- Chasing

Threads could be quickly formed in the lathe by using a chasing tool. This technique has a current following with turners of lidded boxes. The use of the chase produced accurate threads rapidly. One advantage was the ease with which any diameter could be threaded.

Methods (a) and (b) rely on the use of a lathe. Often, however, the workplace could not be lathe mounted. This was especially so with female threads.

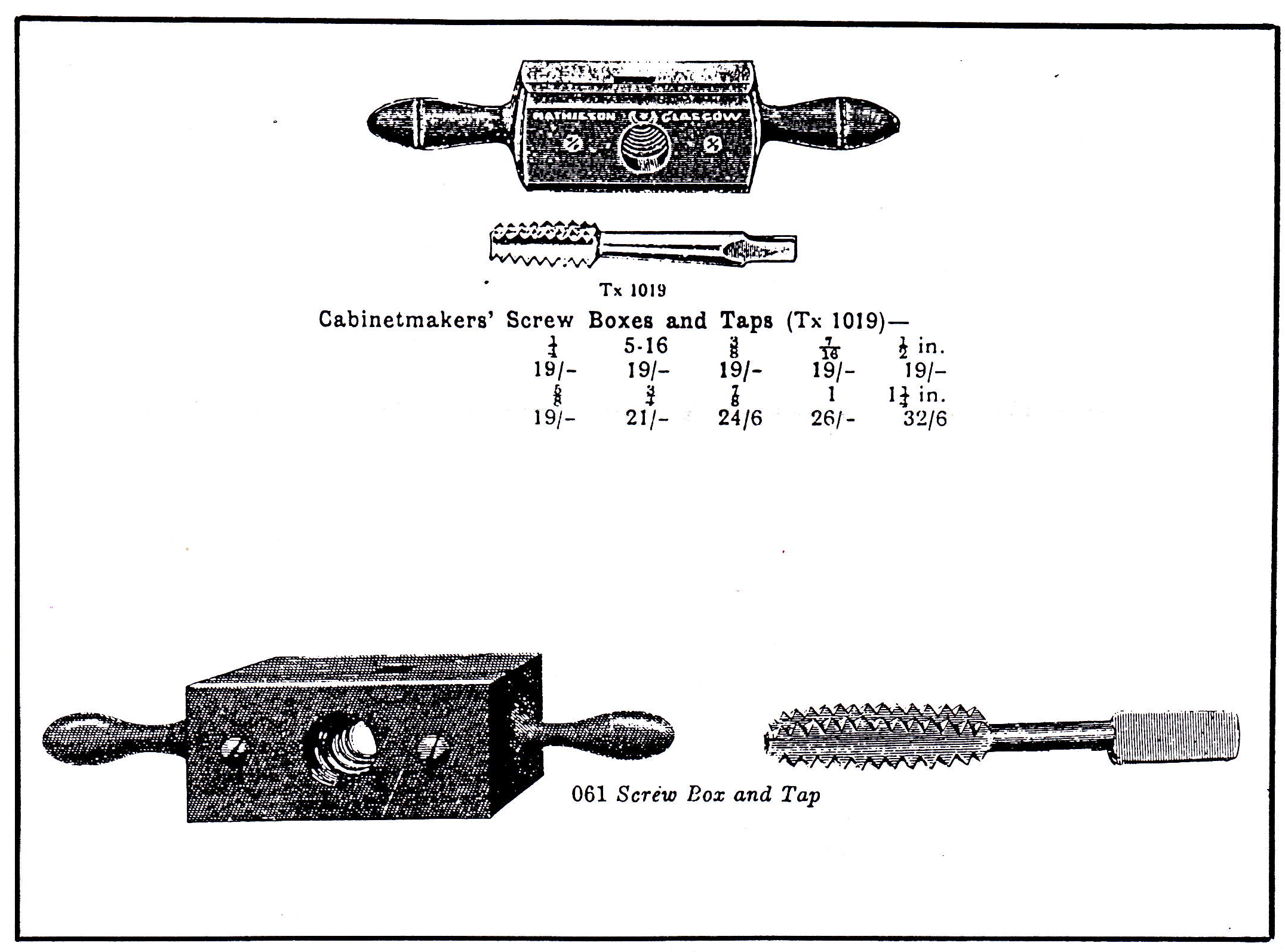

In such cases threads were produced with "screw boxes and taps".

- Screw boxes

These were used to produce male or external threads. As the diameter was not adjustable a number of screw boxes were made. The common sizes ranged from ¼″ to 2½″.

In essence the screw box was merely a V cutter mounted inside the internal thread so as to cut the male thread. The box was bored and taped and the cutter when set reproduced the thread on the workpiece.

Later developments of the screwbox were made in metal but the principle of the cutting action was identical.

- Taps

Taps were made in three forms:

- The solid tap

This was largely used for threads over 2″ in diameter. A wooden cylinder was turned to the diameter of the thread. A helix matching the pitch was cut around the circumference of the cylinder. The cylinder was mounted in a frame where a guide set at the pitch engaged the cut in the circumference. A V cutter was set into the cylinder on the helix. The workpiece was fixed to the frame and the cylinder advanced by the engaged guide moved the V cutter through the bore in the workpiece thus reproducing the thread. Several progressively deeper cuts were necessary.

- The fluted tap

A steel tap was forged, or machined. The tap was threaded with the specified thread form. The tap tapered and had three flutes cut along the circumference of the cylinder. The female thread was largely formed by the deforming action of the tap as it was turned through the bore in the workpiece.

- The hollow tap

To provide a true cutting action the hollow tap was developed. A regular cylinder was threaded with the specified thread form. The bottom of the thread, for approximately twice the length of the diameter, was turned down to the root diameter of the thread. This bottom section was bored out along the tap. The helix was terminated by drilling into the circumference of the tap. This provided a cutting action to the tap. Such taps produced clean internal threads.

- The solid tap

Mechanically produced wood threads:

With the development of the lead screw lathe the principle was applied to producing wood threads. In essence the cutter was fixed in position and the work piece advanced by a lead screw thus producing the desired pitch. The principle is currently used in “router threading devices”.

The lead screw lathe can be used to produce wood threads provided the cutter is suitable. It sounds simple but only an “ornamental lathe” will be found to be capable of obtaining the slow feed necessary.