The term “high speed steel”, or HSS, is derived from the fact that such steel is capable of cutting metal at a much higher speed than ordinary carbon tool steels. The reason for this performance characteristic is that it has a special property known as “red hardness” meaning that the steel is able to retain its hardness even when heated to dull red and so retains its cutting qualities.

HSS is not necessarily a steel conforming to any given analysis but it is some kind of alloy steel. But when tool steels contain a combination of more than 7.0% tungsten, molybdenum and vanadium, along with more than 0.6% carbon, they are generally referred to as high speed steel. Furthermore, HSS is also used for many purposes where temperature is not a factor. This is true, for example, in the case of blanking dies, broaches, certain types of shear blades, etc. Compared to say a 1% hardened carbon tool steel at room temperature HSS in the hardened condition has from five to eight times the wear resistance. Consequently it will hold an edge longer and that means less sharpening and so less down time.

There are many different compositions for HSS. Since the early 1900s a wide variety of high speed steels has been, and continues to be, available. For the most part, these can be divided into two basic types: Tungsten-type, designated T-grades by the AISI; and Molybdenum-type, designated M-grades by the AISI.

Thus by definition, the term HSS includes all the molybdenum (M1 to M52) and tungsten (T1 to T15) class alloys.

These tool steels require very high temperatures for hardening. The molybdenum types are usually hardened from a range of 1200°C (2200°F) to 1235°C (2250°F), the tungsten types as a rule from 1260°C (2300°F) to 1290°C (2350°F) when heat treated in an atmosphere controlled furnace. High-speed tools steels may be hardened to 62-67 HRc and maintain that hardness in service temperatures as high as 540°C (1000°F) making them very useful in high-speed machining.

Perhaps the greatest developments in the manufacture of HSS were not due to changes in composition but improvements in the manner of their manufacture and heat treatment. The electric furnace introduced in about 1906 has been one of the notable advances in the manufacture of HSS; for in the electric furnace a uniformity and refinement of the steel could be attained that had never been dreamed of in the crucible process, which had been in use for many years at that time. Using an electric furnace means that the metal is entirely protected from oxidisation and is capable of a purification unattainable by any other process. The steel is said to be superior to even crucible steel and can be made at less cost.

Tungsten-rich HSS

The tungsten-base steels are the oldest class being an outgrowth of the Mushet steels. The development of Mushet Steel having started in the United Kingdom during the early 19th century with David Mushet (1772-1847) concluded in the later part of the 1800s with his son Robert Mushet (1811-1891).

In 1868 Robert is said to have been the first person to have made alloy steel for commercial use. His steel was the forerunner of all the special alloy steels made today. However, and it may be controversial to say this, but the development of alloy tool steels reached its technical flowering with the work of F W Taylor and M White at the Bethlehem Steel Company in the USA just as the 20th century was dawning. This is the view of the author; others may choose to disagree.

Robert Mushet practiced the addition of manganese to his father’s steel. But he didn’t stop there; he continued to experiment with additive elements and in 1857 discovered the forerunner of the modern high-speed steel we use today. Almost by accident Mushet found that a carbon tool steel with additions of 7 to 12 percent tungsten when left to cool in air from a temperature of 750 to 800°C was very hard. Due to this feature Mushet steels were often referred to as ‘self-hardening’ steel.

Robert Mushet practiced the addition of manganese to his father’s steel. But he didn’t stop there; he continued to experiment with additive elements and in 1857 discovered the forerunner of the modern high-speed steel we use today. Almost by accident Mushet found that a carbon tool steel with additions of 7 to 12 percent tungsten when left to cool in air from a temperature of 750 to 800°C was very hard. Due to this feature Mushet steels were often referred to as ‘self-hardening’ steel.

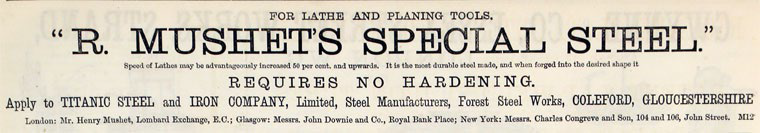

This new steel was immediately put into the market under the name “R Mushet’s Special Steel”. It was billed as being especially manufactured for lathe and planning tools. It was claimed to be superior to any steel at present on the market and, unlike all other steel, it requires no hardening after being forged into a tool.

A typical analysis of this new “Mushet” tool steel was 2.0% carbon, 5.0% tungsten, 0.5% chromium, and 2.5% manganese. Unfortunately for Mushet, the company which was organised to manufacture and sell his new steel, aptly named the Titanic Steel & Iron Co Ltd, did not last the distance. Things at Titanic began to go wrong and by June 1871 the production of Mushet steel was taken over by Samuel Osborn & Co Ltd at the Clyde Works, Sheffield.

With a better business model, the wide introduction of the new steel into engineering works and its imitation under the name of air- or self-hardening

steel quickly followed. Clearly a substantial advance had been made in the art of cutting metals. It was now possible to turn or plane at double or triple the former speeds; and to machine pieces formerly quite too hard for the tools available or so hard as to make the cost of operation prohibitive. But even after gaining general use in engineering works, Mushet tools were little used for increasing speeds – most usually only to save frequent grindings or to permit doing jobs previously impossible.

This type of steel although of remarkable cutting and wearing qualities could not be adapted for finishing or fine work where the cut had to be smooth. This was due mainly to the coarse grain of the self-hardening steels which did not allow tools made from it to take a keen cutting edge such as would leave a good finish. So the “Mushet” steels were used chiefly for tools used for coarse and heavy work. This difficulty was rapidly overcome as the new High speed steels were developed.

A fuller treatment of the Mushet story can be found in Ralph Anstis’ book “Man of Iron – Man of Steel” published in 1997. It is quite a good read.

It took a further 25 years after ‘Mushet’ or ‘self-hardening’ steel had become an established fact in engineering before the marvellous properties latent in it were clearly appreciated and the industrial world caught a glimpse of what promised to be a revolution in machine shop methods.

Frederick W Taylor had begun experimenting with Mushet and other self-hardening steels as far back as 1893 when his consulting engineering company was engaged by the Bethlehem Steel Co. His aim was to determine which steels were best suited to special kinds of work. So shortly after he arrived at Bethlehem Steel in 1898 to solve an expensive machine-shop capacity problem he formed an association with Maunsel White and others (such as C G L Barth) so as to be better able to undertake the work at hand.

After leaving Bethlehem Steel, Taylor focused the rest of his career on publicly promoting his management and machining methods through lecturing, writing, and consulting. Eventually Taylor and his scientific management methodologies become famous worldwide. In 1911, Taylor introduced his “The Principles of Scientific Management” paper to the American Society of Mechanical Engineers.

Before the introduction of HSS in the USA the term ‘Mushet steel’ meant a self-hardening tool steel containing tungsten. These early ‘Mushet’ steels contained from 5-8% tungsten, up to 2.5% manganese, and very high carbon (1.5-2.4%) with sometimes 0.5% chromium. The Mushet steel made by Samuel Osborn & Co Ltd in 1868 and branded ‘Self-Hard’ or R.M.S. had a typical analysis of 6 to 8% tungsten, 2.4% carbon, 1% manganese and 0.55% chromium. But gradually changes were made in the contents of the steel with tungsten content being raised from 8% to 14%, an increase in chromium and lowering of the manganese.

By 1899 the “self-hardening steel” had become “air-hardening steel” as it was found that if the tools made from R.M.S. were reheated to “a good scaling heat” after hardening and placed in a draft of air to cool quickly, they were better

than tools left to cool naturally in air from the hardening heat. This was said to have been discovered accidently by Henry Gladwin who was employed by the company to advise firms on how to harden R.M.S.

These changes culminated in the introduction in 1900 of “Mushet” high speed steel. The first use of vanadium in HSS was made a few months later by Frank A Hurst, who joined the company in 1897, the reputation of the company and the steel was further enhanced. It marked another milestone in the history of tool steels.

The Taylor and White experiments from 1893 to 1898 led to a new steel with less carbon. Taylor-White steel of c.1900 contained 1.85% carbon, 8% tungsten, 3.8% chromium, and 0.3% manganese (the blend changed over time and by 1927 the Taylor-White HSS contained 0.75-1% carbon, 8.5% tungsten, and 3% chromium). The claim by Taylor and White from the Bethlehem Steel Co of America to have invented a new tool steel was contested as was their application for a patent. But, finally, on 19 February 1901, Taylor and White received a US patent for a ‘Metal-Cutting Tool and Method of Making Same’ such a tool being "specially adapted for cutting very hard metal and capable of running efficiently when cutting such metals at higher speeds and greater temperatures than has heretofore been practicable".

The intrigue, technical status, discoveries, players, legal aspects and importance of this period have been recorded and analysed in detail in a 1933 paper by Arthur Townsend. For those interested in another side of F W Taylor’s business activities the 1986 article by Wrege and Greenwood is well worth reading. Details are cited in the references.

For the next part of the series: Tool Steels: A Brief History — Part 3 High Speed Steel

For the start of the series: Tool Steels: A Brief History — Part 1 Introduction